Standard ERP-integration

RS Production is often integrated with other systems.

This feature is included in the addon

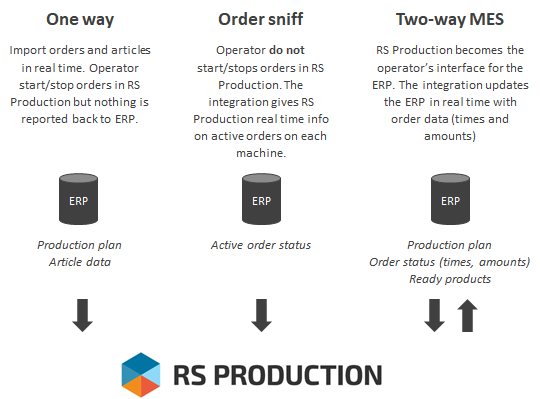

The Integration Interface offers several different ways to do integrations.

Three types of ERP-integrations

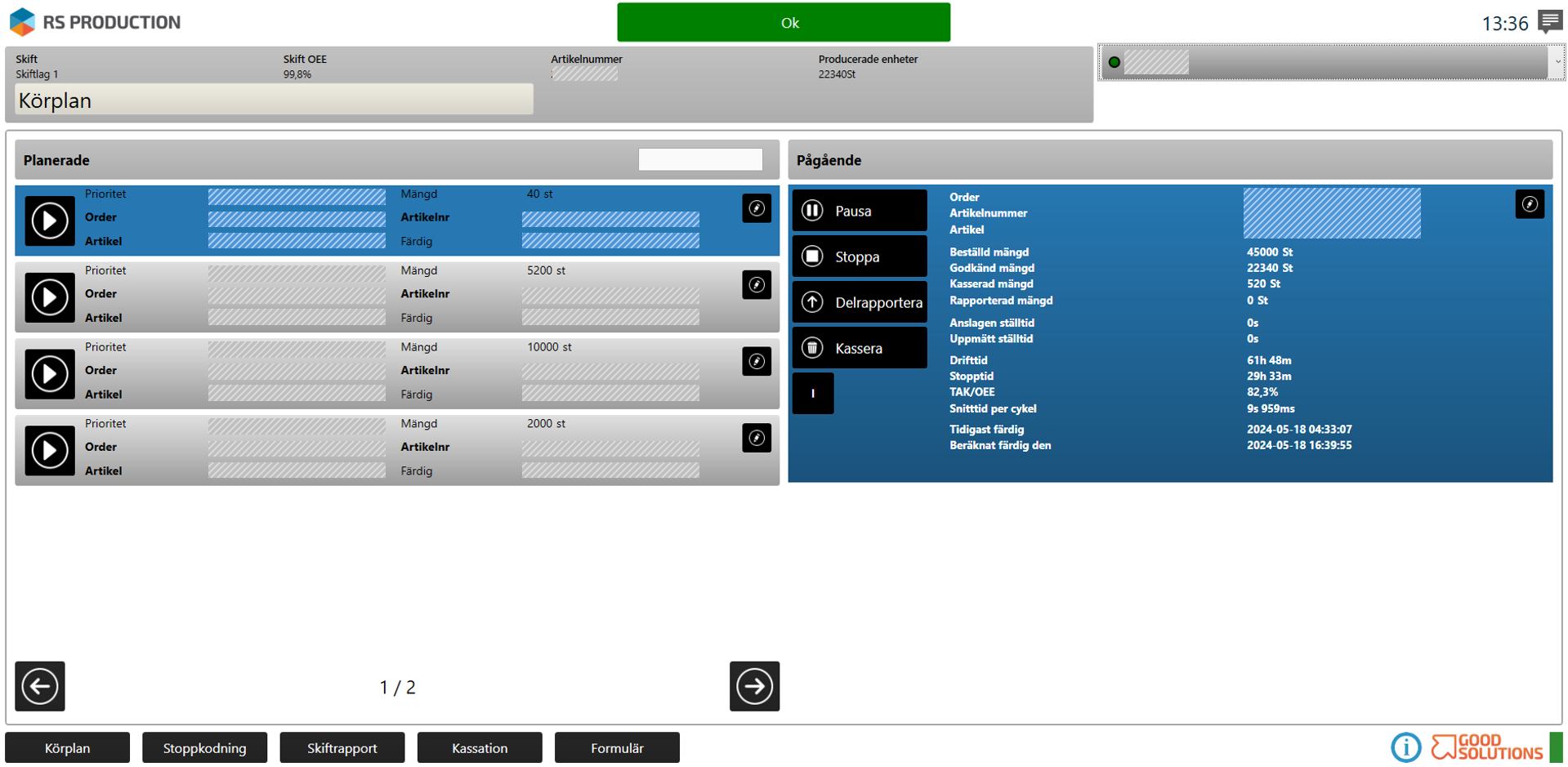

Operator tools user interface for One way

The integration automatically populates production orders and articles on Operator tools' Production Plan page.

Read more about Production runs and how that works.

Operator tools user interface for two-way MES

The user interface extends Operator tools' Production Plan page with a new reporting page.

Read more about Production runs and how that works.

Button | Function |

|---|---|

Play (on left side) | Starts a new production run for the selected order/operation. Read more about Production runs. Will set the ongoing production run to status=run in RS Production and will send status=run on the order/operation to the ERP. |

Pause | Will set the ongoing production run to status=pause in RS Production and will send status=pause on the order/operation to the ERP. |

Stop | Opens up the Reporting page (see below) and will stop the ongoing production run after the report. Will send status change on the order/operation to the ERP. |

Part report | Opens up the Reporting page (see below) and will keep the ongoing production run running after the report. Will send status change on the order/operation to the ERP. |

Scrap | Manual scrap registration. Opens up Operator tools' scrap page. |

! | Show information text on the order/operation/article coming from the ERP |

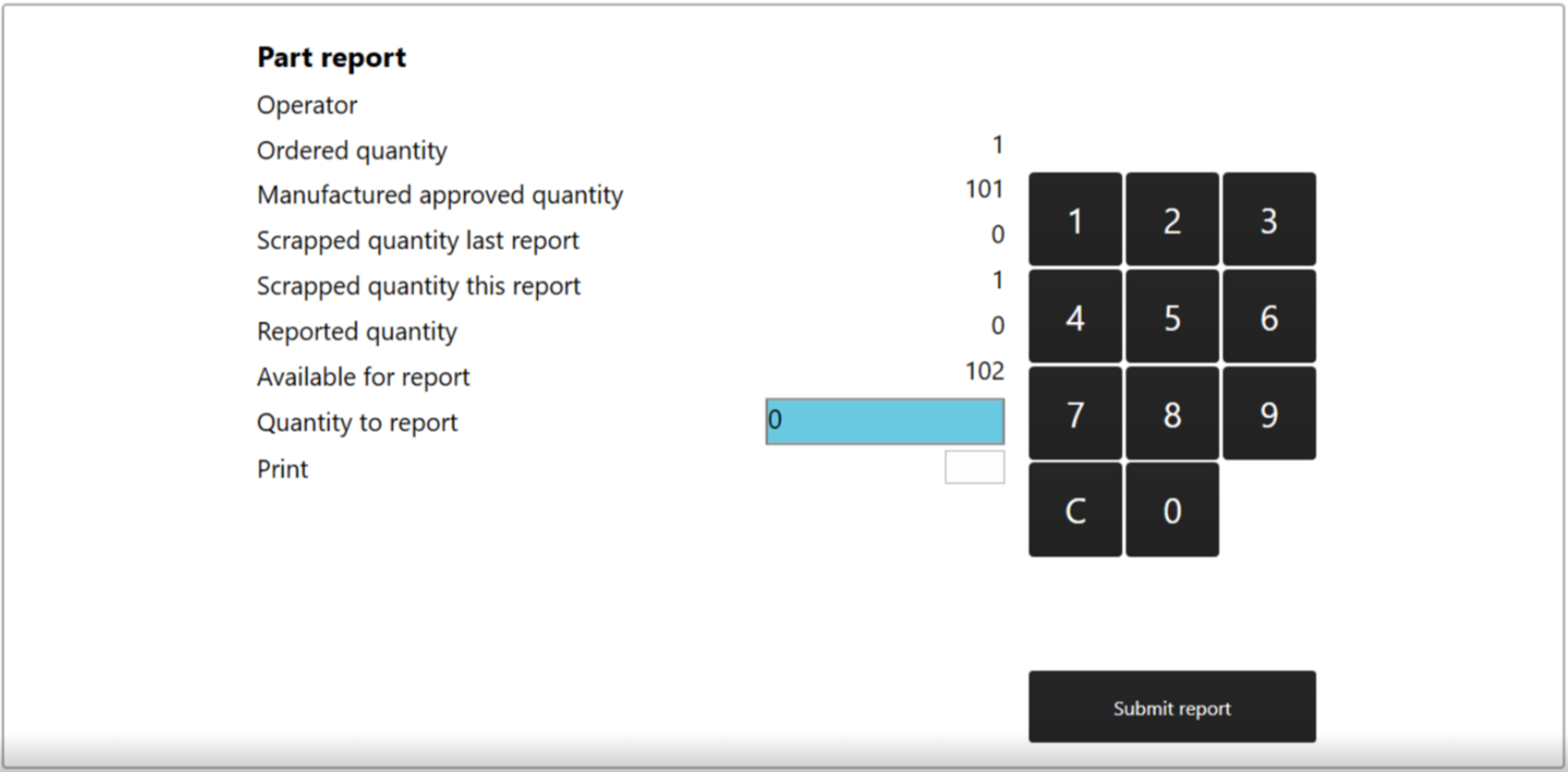

Reporting page

This page gives the operator a chance to look at the figures before they are reported to the ERP.

Read more about Production runs and how that works.

Field | Function |

|---|---|

Operator | Name of the operator(s) clocked in. This information is sent through in the integration and can be used in the ERP. Read more about how to Handle Operators |

Ordered quantity | This is the ordered amount on the order/operation coming from the ERP via the integration. This is shown as information to the operator. |

Manufactured approved quantity | This is the total amount of approved on the ongoing production run. This is shown as information to the operator. |

Scrapped quantity last report | This is the amount of scrap that has been previously reported to the ERP in the previous reports on this production run. The scrap amount that can be reported in this report is not included here. This is shown as information to the operator. |

Scrapped quantity this report | This is the amount of scrap that has yet not been reported to the ERP in the previous reports on this production run. This means that this is the scrap amount that will be reported in this report. This is shown as information to the operator. |

Reported quanity | This is the approved amount that has been previously reported to the ERP in the previous reports on this production run. The approved amount that can be reported in this repor is not included here. This is shown as information to the operator. |

Available for report | This is the approved amount that has yet not been reported to the ERP in the previous reports on this production run. This means that this is the maximum amount that can reported in this ( report (in the field below). This is shown as information to the operator. |

Quantity to report | This is the field where the operator write the approved amount to send in this report. |

Print (Optional) | Mark this, and the integration will tell the EPR to also print a pallet label. |

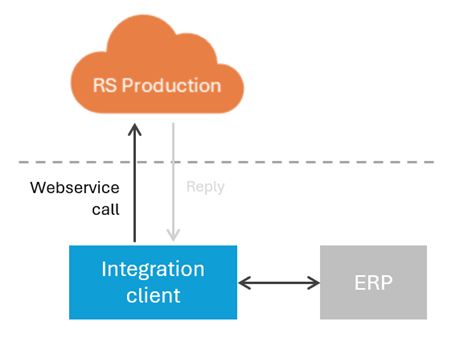

Webservice API (REST API) (one way, or two ways)

RS Production has a HTTP API that exposes the RS Production “in memory database”. The API calls are made over HTTP with standard Get / Put and Post methods, the data can be serialized in either XML or JSON format.

What systems are typically connected like this? | ERP, MPR, APS |

What data can be written? | Order/operation status, Produced/scrapped/approved/reworked amount, Amount ready for stock, Machining time, Changeover time, Cycle times, Time per approved unit |

Order data import

Field | Comment |

OrderNumber | NOT NULL |

OperationNumber | If the same order is available on more than one machine an operation number may be handy |

OrderedQuantity | NOT NULL |

OrderERPStatus |

|

PlannedStartDate |

|

PlannedFinishedDate |

|

PlanningGroup | NOT NULL. The group that the order should be available on. A planning group could be one or more machines. The configuration of which machine(s) that belongs to a planning group is done in RS Production. |

Priority | Orders are sorted by this number in the Operator UI if available. |

ReportNumber | When a report is created in RS Production this number will be added to that report. |

Article data import

Field | Comment |

ArticleNumber | NOT NULL |

ArticleName | NOT NULL |

ArticleType |

|

ArticleInstruction |

|

AllocatedChangeoverTime |

|

OptimalCycleTime | The optimal cycle time is the time it should take for the machine to produce one unit * UnitFactor. |

AmountPerCycle | Factor for calculating produced amount from number of captured machine cycles. If not provided 1 will be used as default |

All article fields will be combined to form an article object in RS Production. If the article number already exists a new one will not be created, but the existing will be updated.

If there are more than one row with the same article number but different article names, instructions or type, the data in RSProduction may change every read, so avoid it.

All fields with NOT NULL (except ID) will have to be Provided by the integrator.

Reporting of order data

Field | Comment |

Created |

|

OrderNumber | |

Executed | |

ExecutionDate | |

ReportedApprovedAmount | |

ReportedScrappedAmount | |

ReportedMachineTime | Time in minutes, only value adding time. Downtime not included |

ReportedChangeoverTime | Time in minutes, only changeover time. Other downtime not included |

FinalReport | |

PartialReport | |

PauseReport | |

Delayed | |

AmountOnPalletLabel | |

PrintPalletLabel | |

ReportingNumber | |

StartReport | |

OperatorsName | |

Operator | |

ProductionRun |

SFTP-interface

Used to transfer data to RS Production cloud service.

What systems are typically connected like this? | ERP, MPR, APS, EAM, BI, and more … |

What data can be read? | |

What data can be written? | Order/operation status, Produced/scrapped/approved/reworked amount, Amount ready for stock, Machining time, Changeover time, Cycle times, Time per approved unit |

How to connect? | The SFTP service is running on the RS Production cloud (port 22). Login using SSH. Each user has their own directory to ensure no data is mixed. |

CSV-file import (one way) (Addon Integration Interface not needed)

What data is integrated like this? | Mainly used to for one time import of article/product data, often at system setup. At the moment, there are no standard CSV-file structures ready to be imported. But any RS Production delivery consultant can set up any type of import needed. |

What data can be imported? | Most common is articles (products) and their properties, but any part of the RS Production data model can be imported this way. |

How to connect? | Contact your RS Production delivery consultant to help you set this up. |

Go here to read more about how to do CSV-file import and Import orders from CSV-file.