RS Production OEE

Find your factory’s hidden capacity, become more resource efficient

RS Production® OEE gives you the insights needed to make better and fact based decision. It help you cut production costs, get real-time control, and use fewer resources per produced unit. Improving Overall Equipment Efficiency (OEE) is both profitable and sustainable.

No more need for spreadsheets, pencils and paper for production follow up. Get a ready-to-start configuration up in 5 minutes with the guided wizard.

Make better, fact-based decisions

Automatically identify machine time losses in real-time. Operators can add their unique domain expertise with loss codes, comments, and more using a touch screen at the machine.

Easily understand data from machines and operators with standard reports designed to help your teams make fact-based decisions.

Get insight into production losses, react quickly and accurately to deviations, and get visual facts for your meetings and improvement work.

Features

Look here for Products, variants and functionality

OEE

Complete OEE capabilities including

automatic (or manual) downtime, speed loss and scrap logging

manual and/or automatic reason coding

Downtime

Speedloss

Scrap

Rework

automatic changeover logging

Machine monitoring

OPC UA, 24V signals and Webservice API are the most common machine interfaces to capture machine data and events.

uptime/downtime

production cycles and produced amounts (incl scrap and rework)

current article/product and order

automatic stop and other loss information

Read more about OPC data integration

Block and release

Evaluate a product with quality defects. Should it be discarded, reworked, or can it continue in the flow as is?

blocking and releasing

printing pallet flags

First time pass (PPM) analysis reports

Plug and play with RS IoT box

Use our self designed RS IoT box to easily capture machine signals to the cloud service

Data capture over 4G network or factory WiFi

8 inputs per box

Learn more about RS IoT - Technical Data

Production follow up

Follow production net-output per production run (order or article) by

produced amount

produced, scrapped, reworked, approved amount

product/order run

production order plan

Visual operator screens

Provide operators with relevant information such as

production plans

loss coding

visual shift targets report

Read more about RS Production Operator tools user interface

Reports and KPI's

50+ standard reports including

pareto charts

OEE waterfall

cycle time analysis

change over matrix

various filter and sorting

automatic report e-mails and prints

Live TV-screen dashboards

Visualize live production status factory wide using

a range of standard TV-screens

no-coding customization

25+ visual components

Learn more about RS Production Screens

Mobile access

Live production data at your fingertips with mobile

OEE

production output

production times

messaging (chat) system

iPhone, Android, Windows support

See more about RS Production Mobile

Loss analysis

No extra software is required to optimize production by analyzing

OEE and losses

combine dimensions

loss drill down reports

Messaging system

Enable team communication inside your factory with

direct messages

message groups for relevant communications within or cross organizations

Integrations

production plans and orders

articles/products

production data (

Go here to read a Guide to MES-integrations

Cloud operated

RS Production is generally cloud operated.

Learn more about Cloud service and data security

Operator tools

Here’s a selection of features in Operator tools

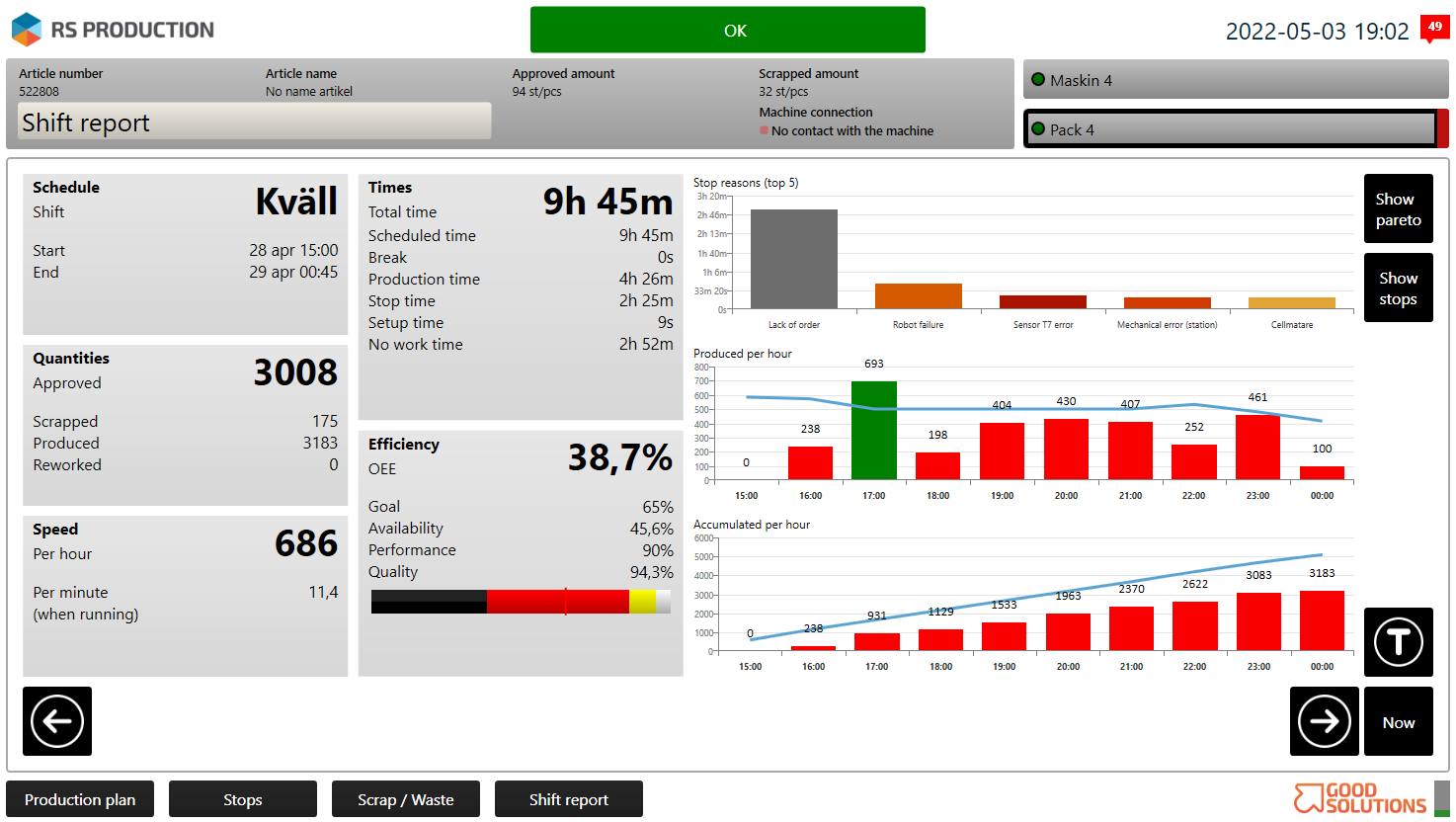

Real time overview of status against plan and top losses.

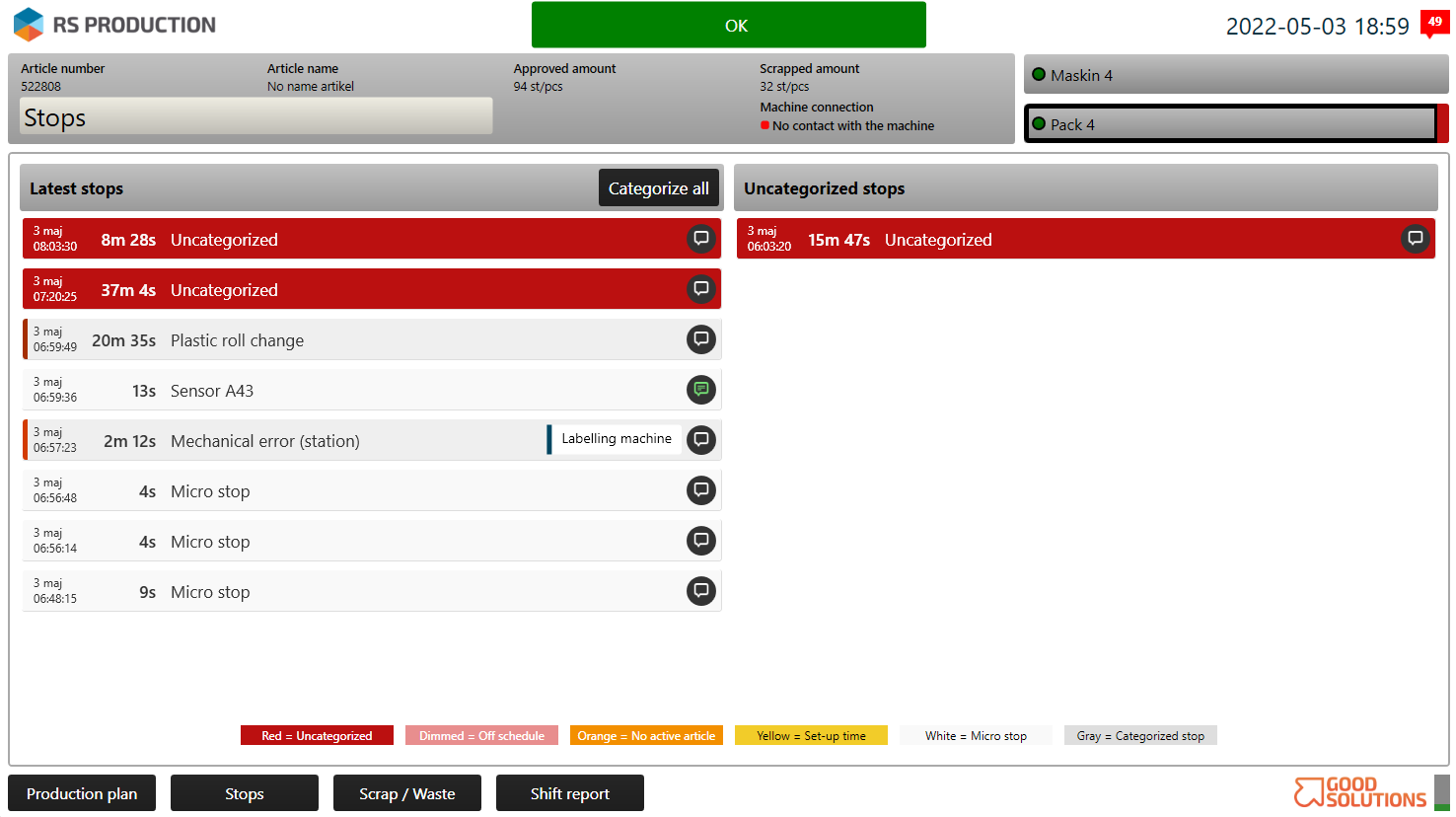

Real time view of OEE losses and visual user interface for operator to add reason codes and comments.

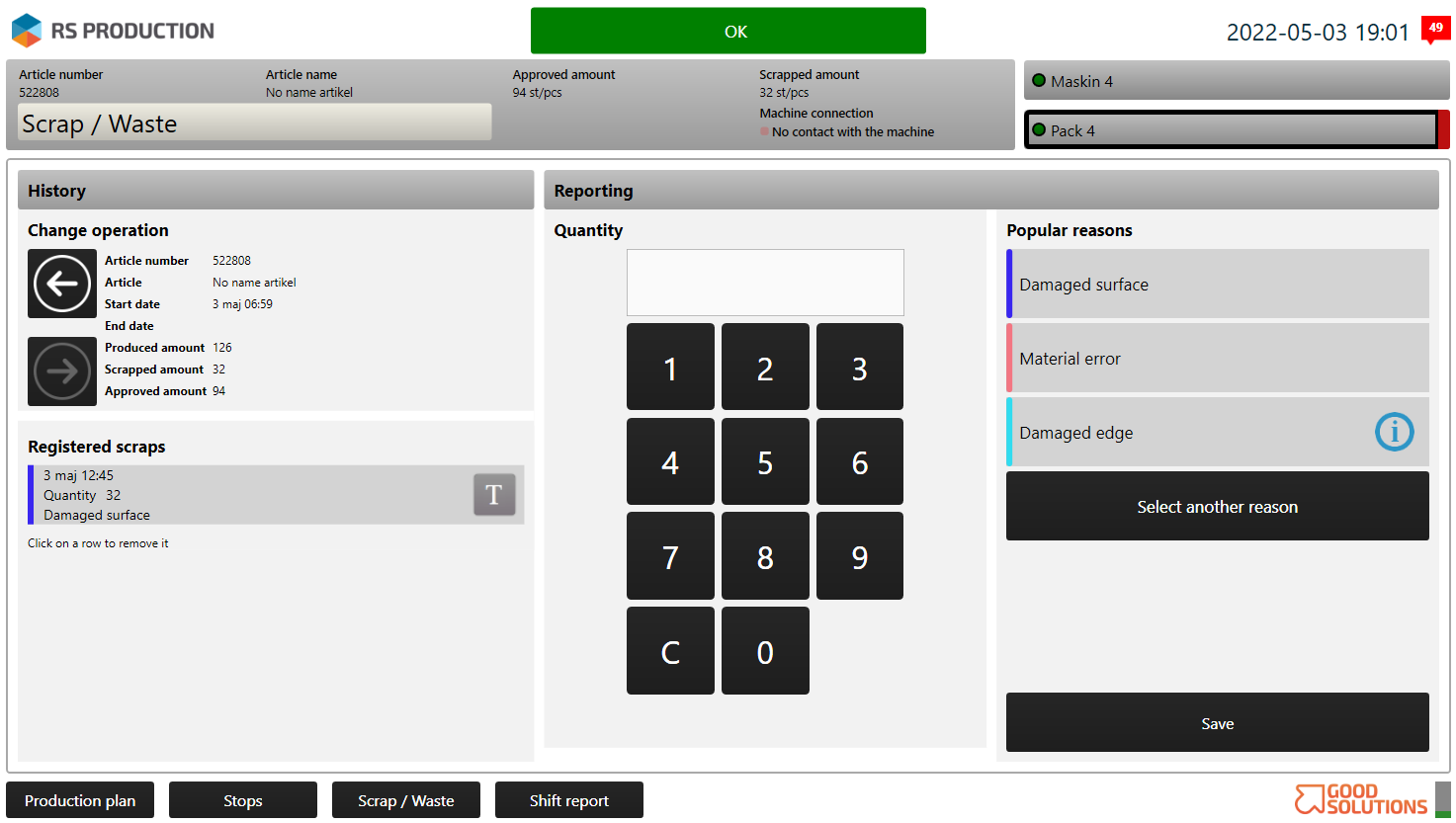

Scrap and rework registration

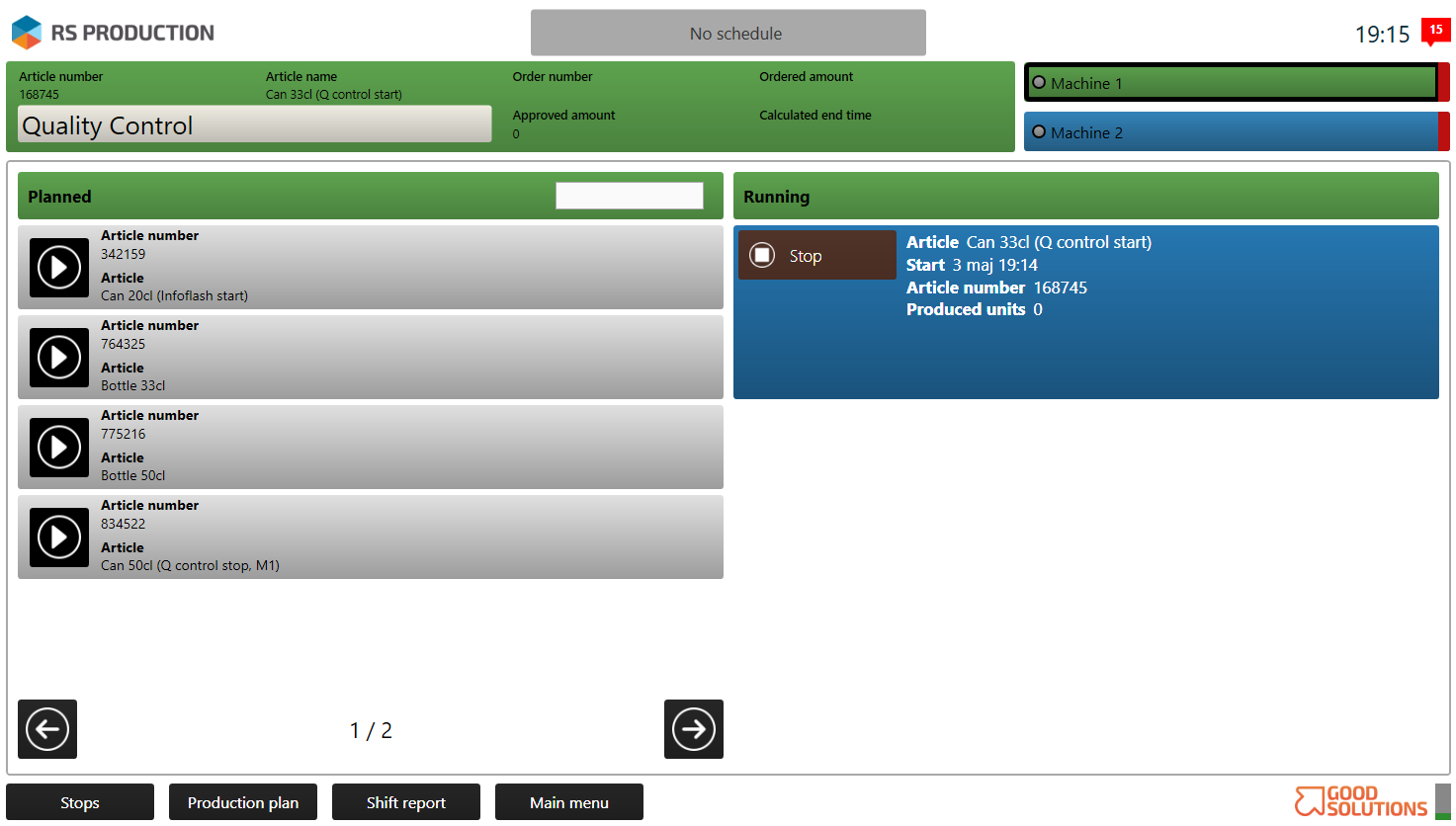

Visual production plan to change running order and/or item (article)

Reports and analysis

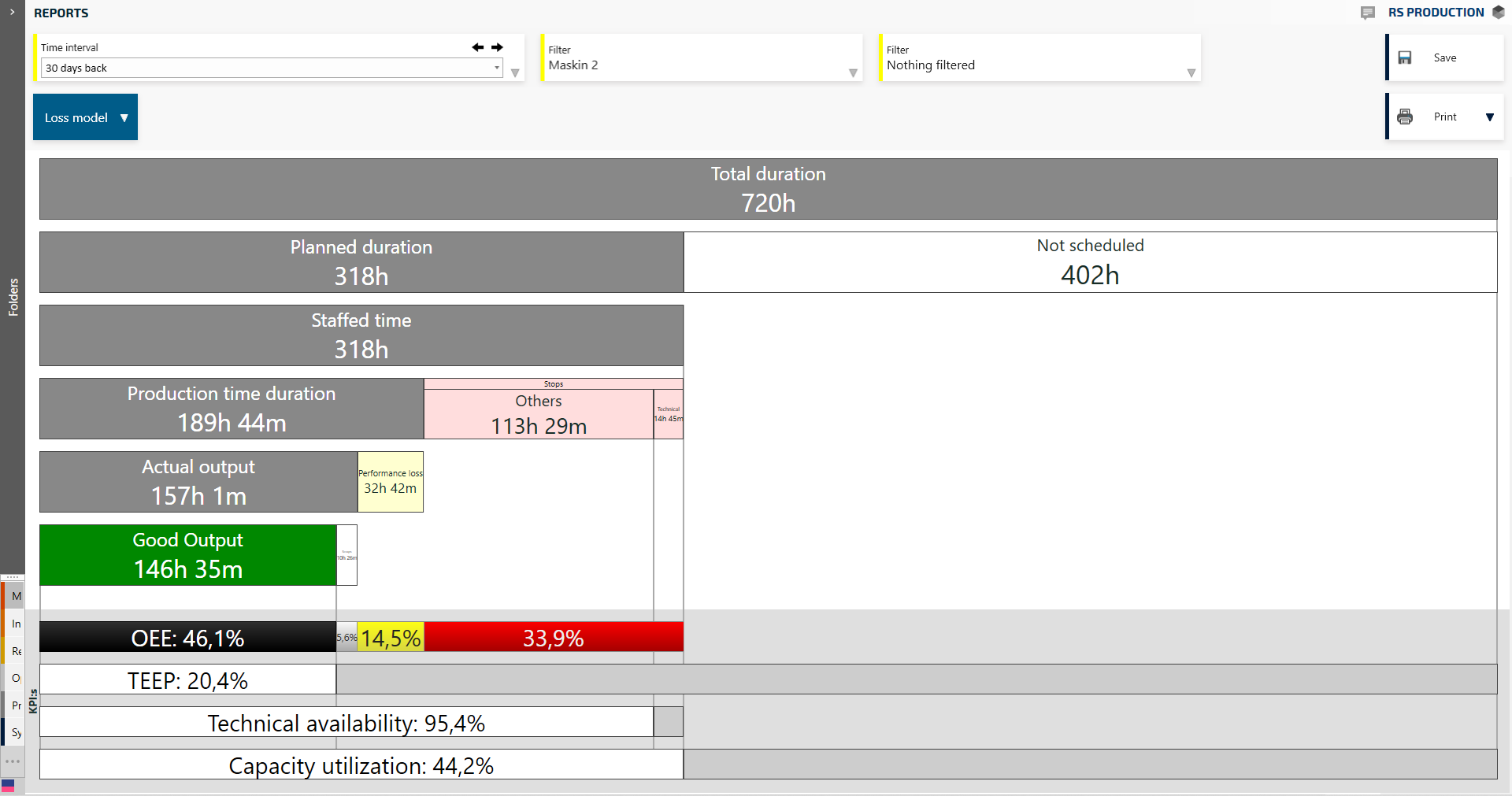

The visual OEE loss model reveals the hidden capacity in machines and factories.

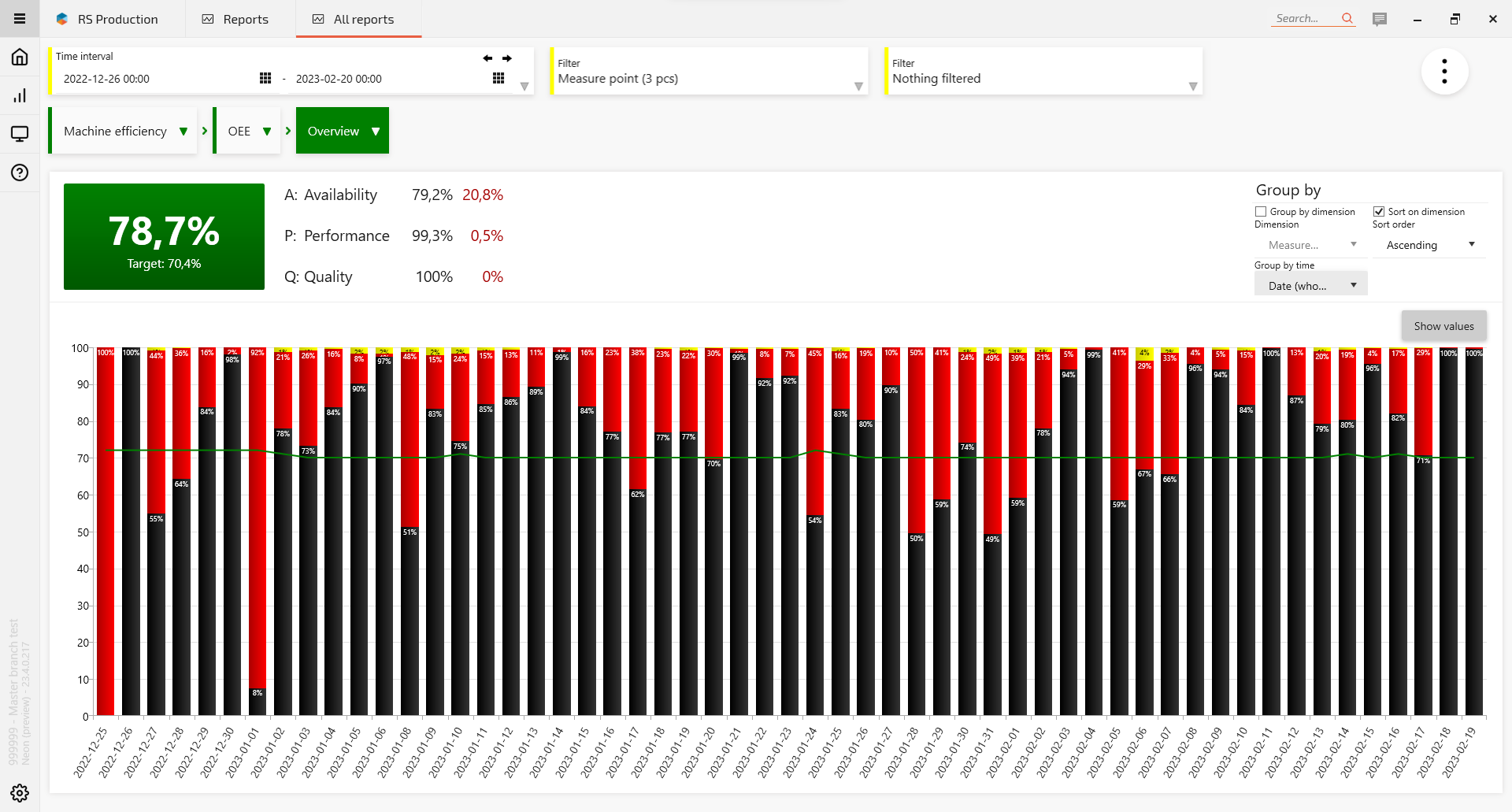

The OEE overview report helps understanding more about the OEE losses. Click to drill down and the underlaying reasons.

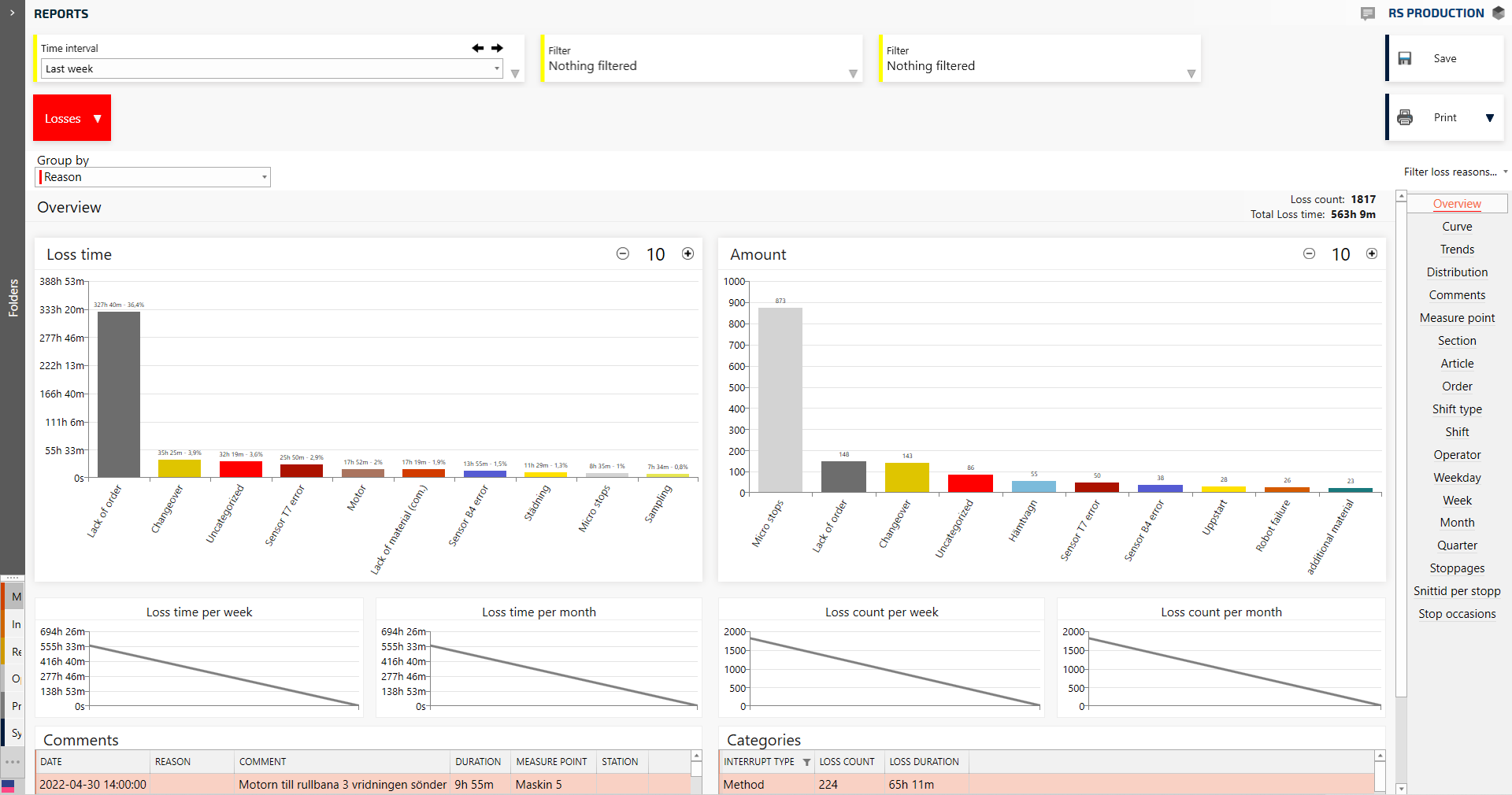

Visual pareto diagrams show the reasons behind the OEE losses.

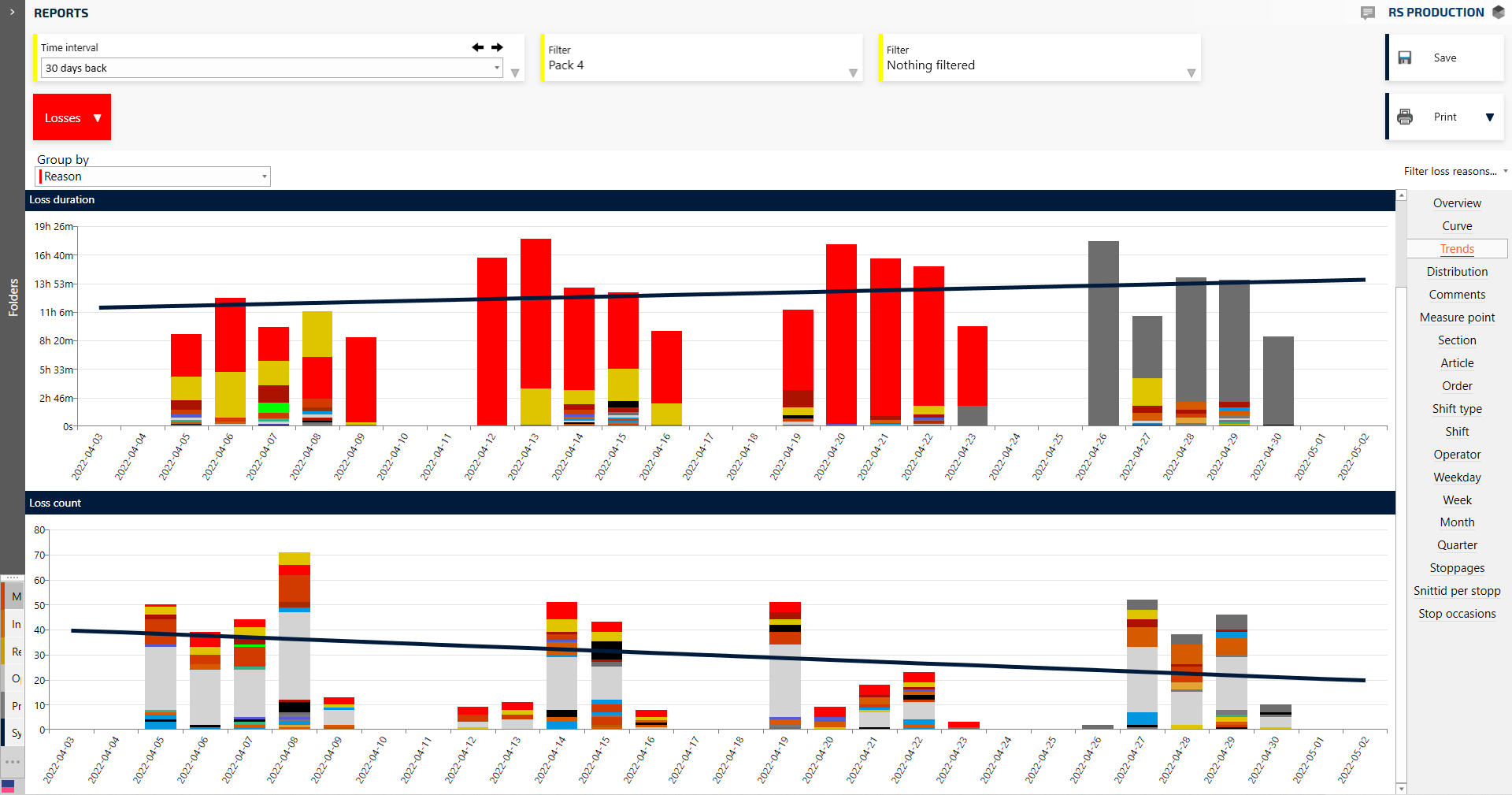

Follow the development of losses over time.

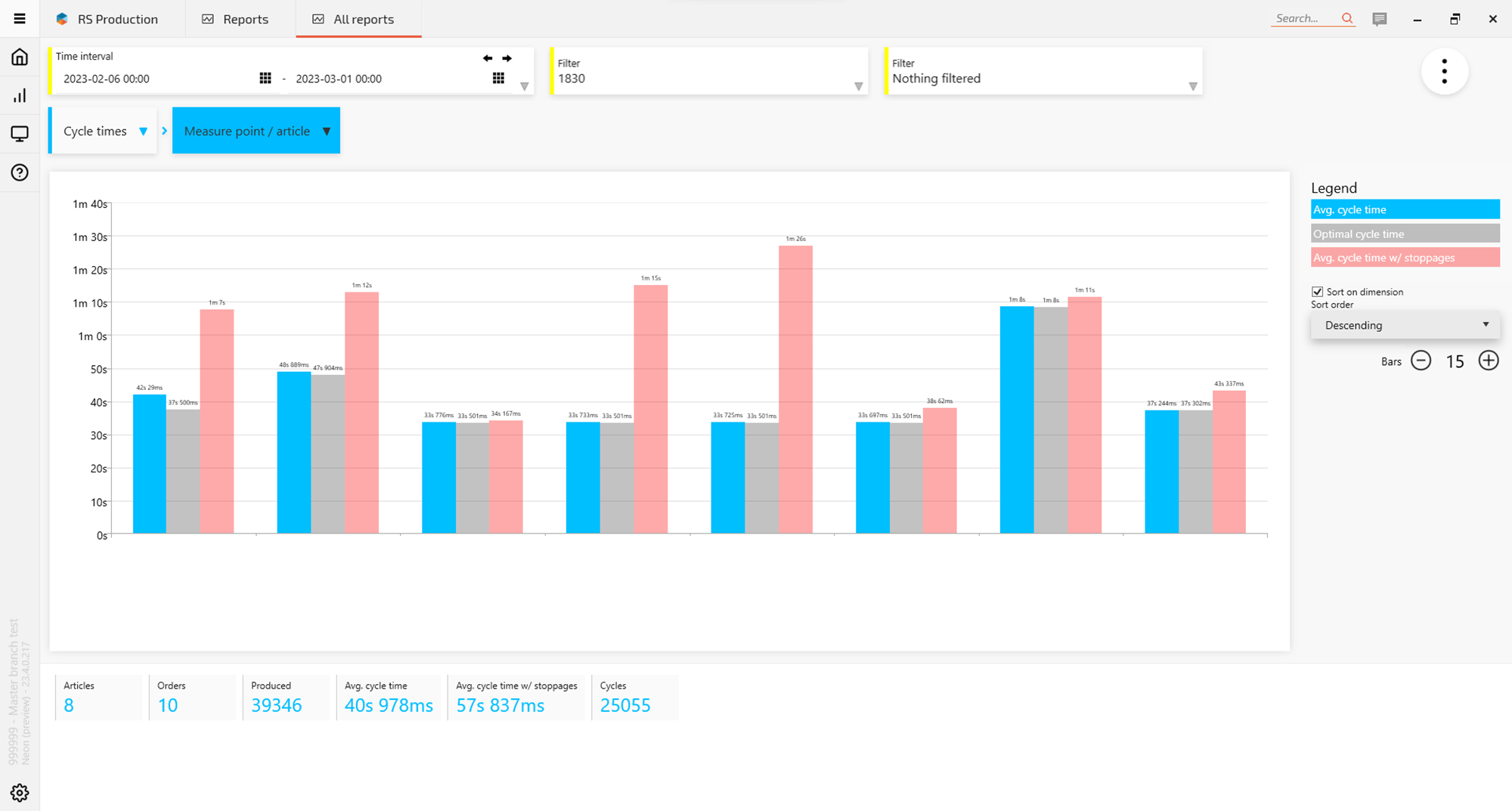

The cycle time analysis shows the true cycle times and efficiency factors to use in planning and cost calculations.

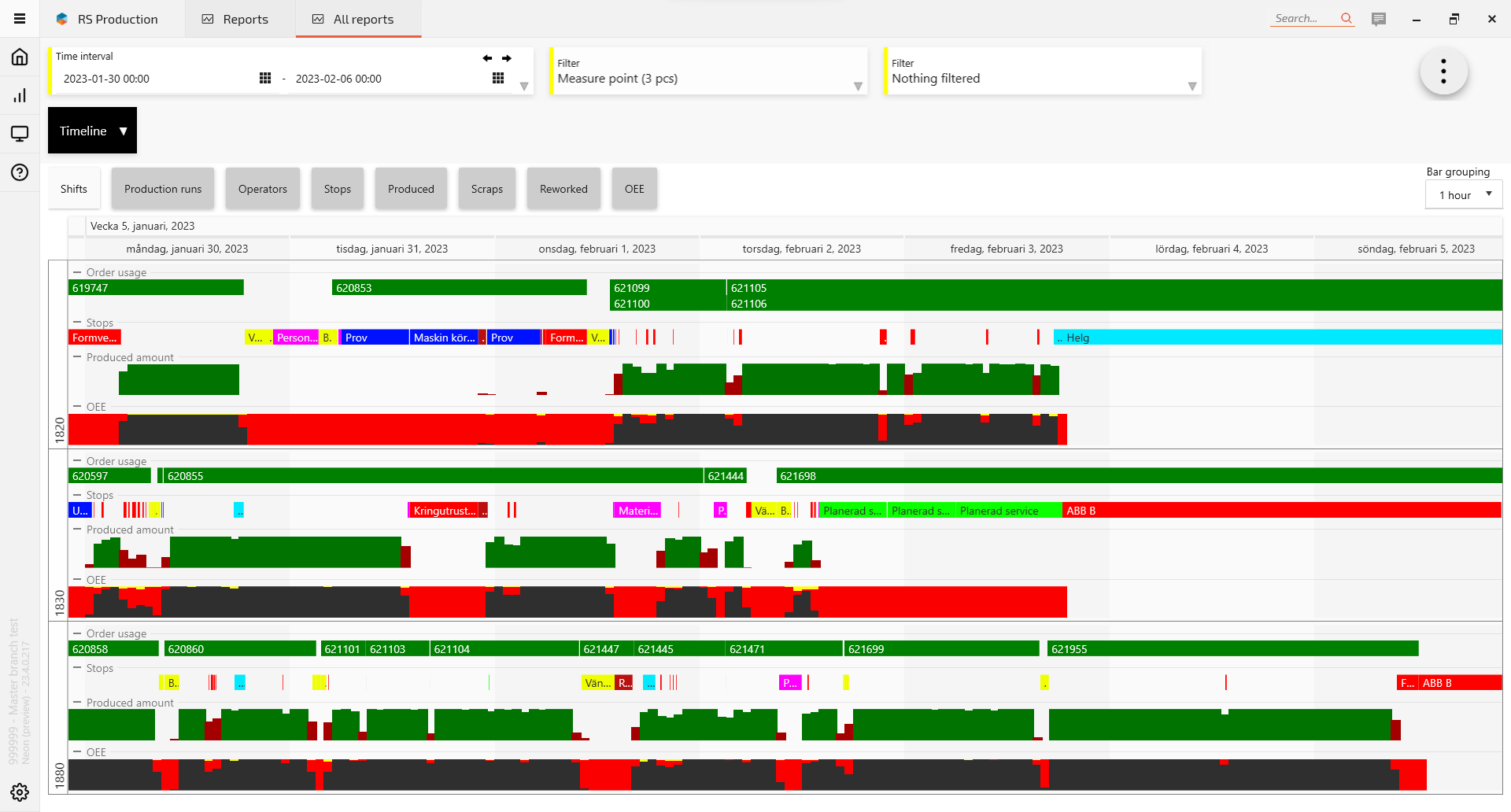

The real time timeline report adds transparency and tells exactly when something happened.

Office tools

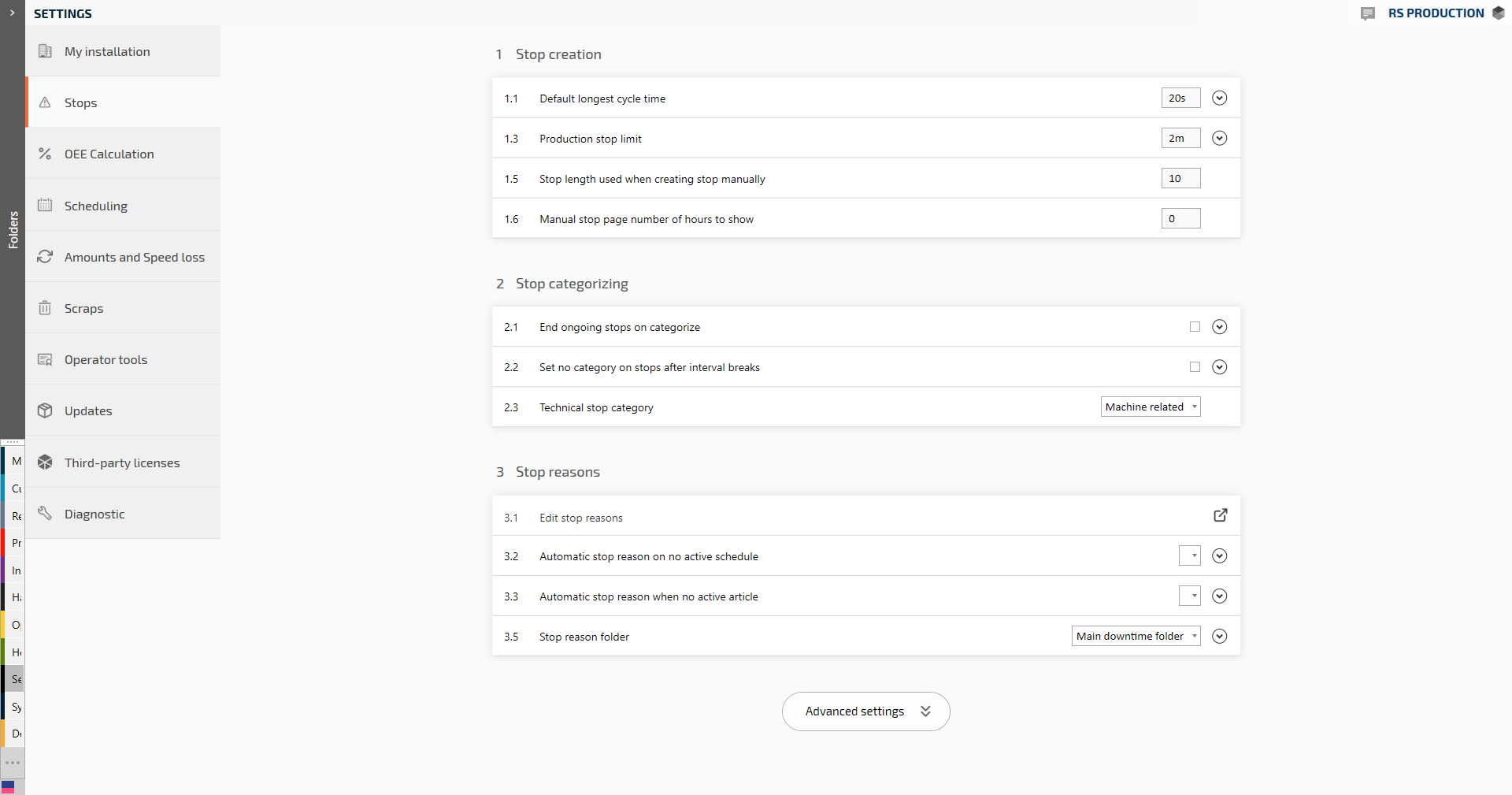

Easy to use settings interface to help you to have a system that is up to date with your needs.

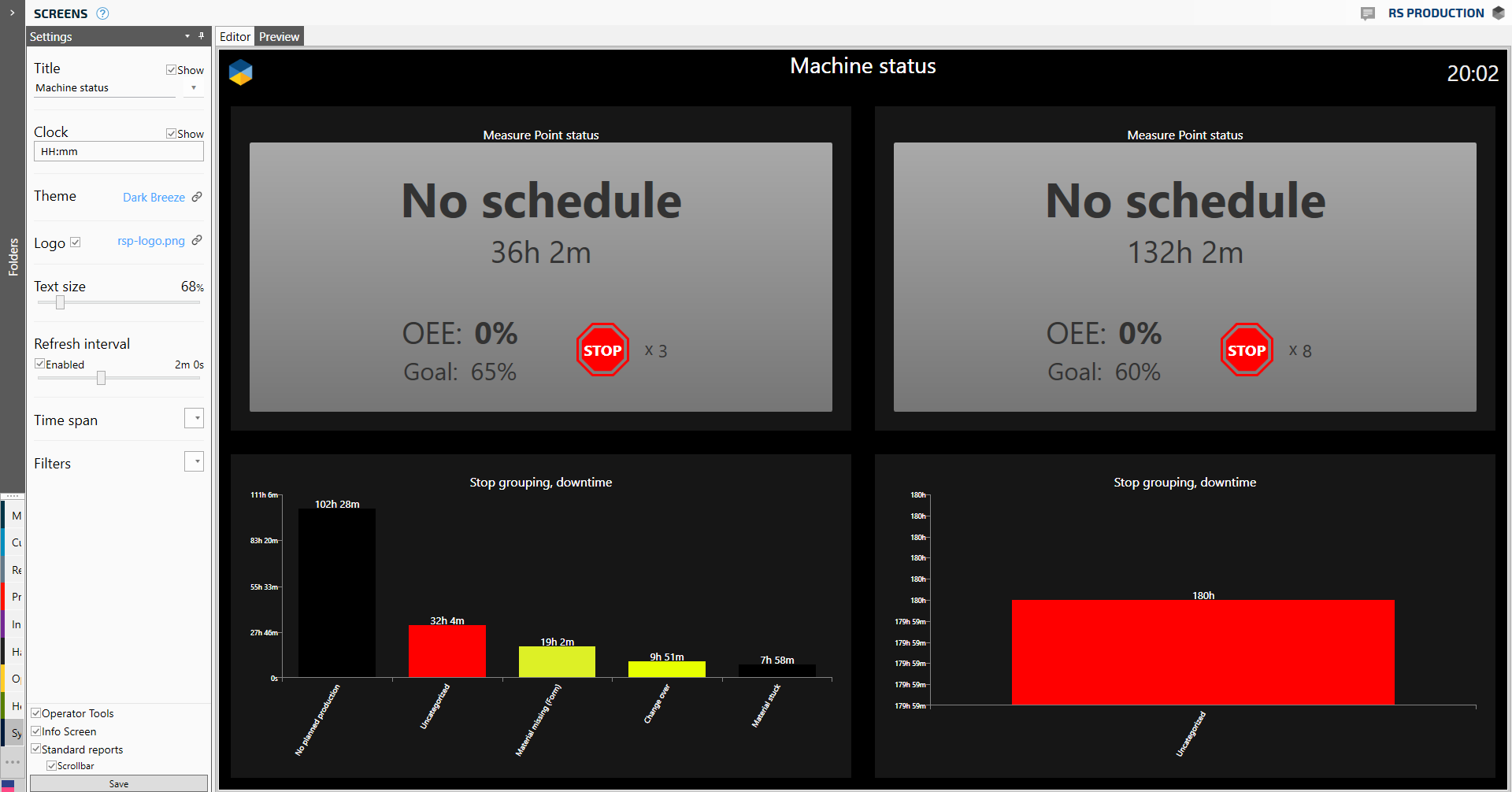

Use the Screens tool to configure your own report pages with no code writing. Select from +30 different visual standard components and adjust the dashboards when your teams need for facts changes over time.

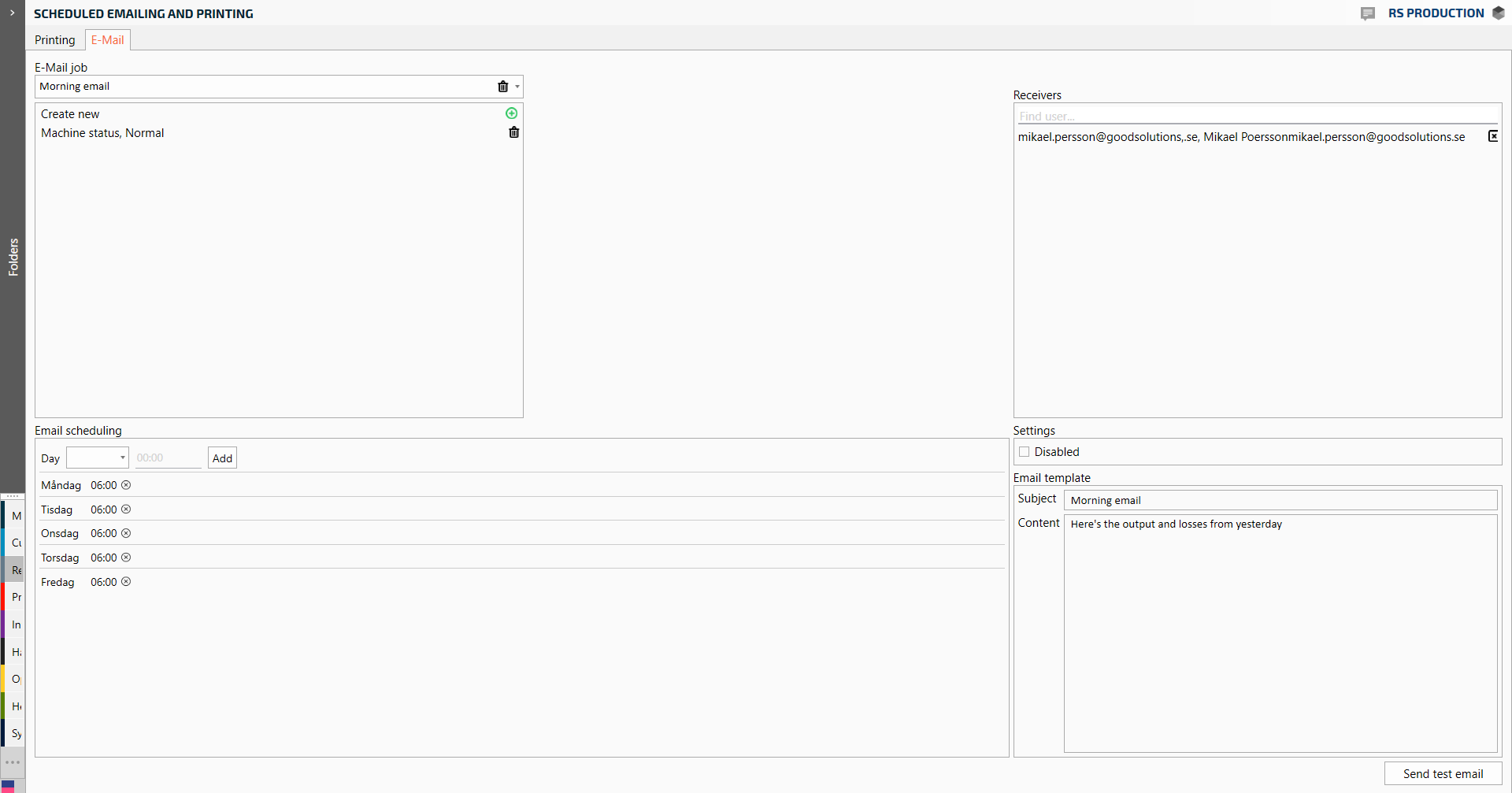

Support different roles and meetings with facts automatically with scheduled emails and print-outs.

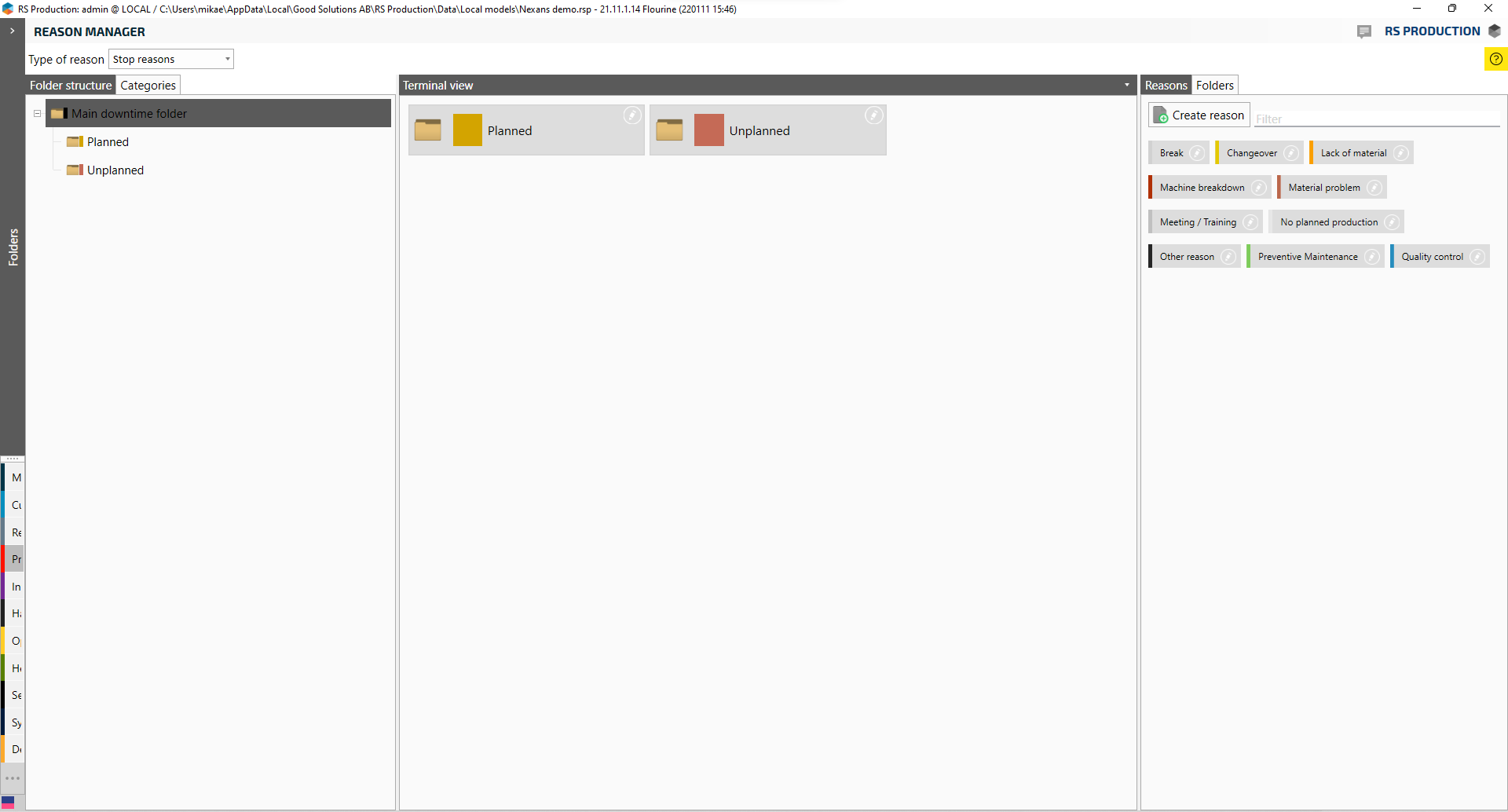

The visual reason manager helps to setup and maintain reason codes for downtime, speedloss, scrap and speed loss. Assign different reason codes to different machines and types of production processes. Group reason codes in categories to get a high level overview.

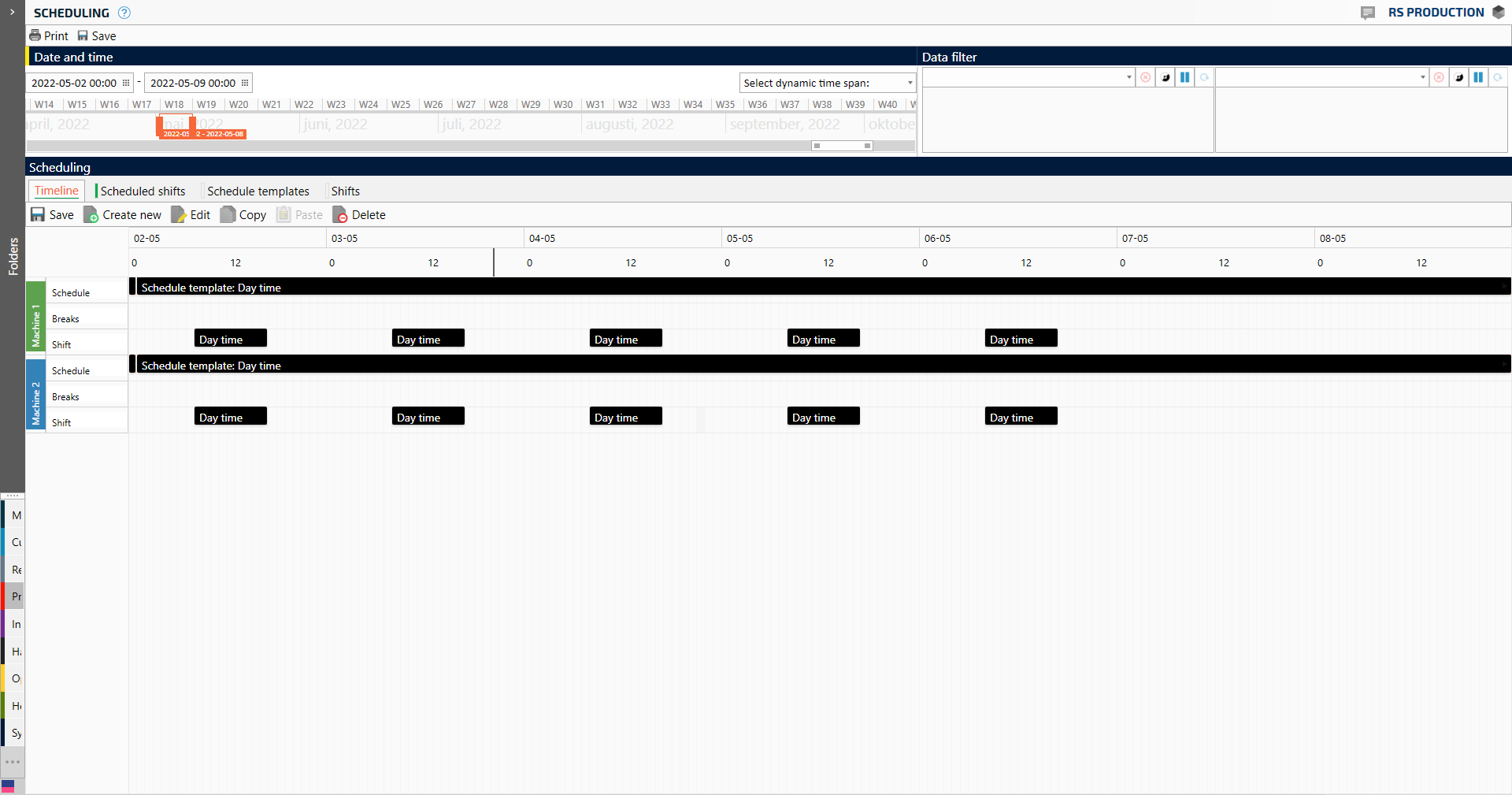

Use the visual scheduling to define shift schedules and machine time calendar. Automatic scheduling into the future. Handles breaks and planned shifts.