Guide to MES-integrations

Many factories use RS Production as their MES-system.

Data integration

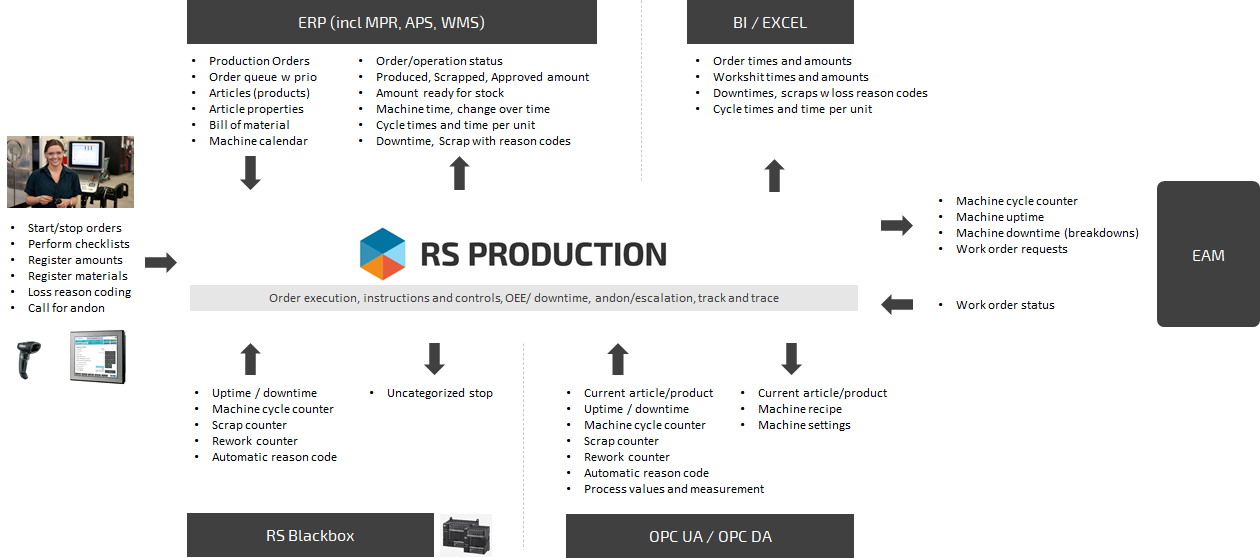

Below is a selection of typical integrations in a RS Production MES using both standard and custom integrations.

From/to ERP (incl MPR, APS, WMS)

RS Production gets

Production orders

Order queue with prio

Articles (products)

Article properties

Machine calendar

RS Production returns

Order/operation status

Produced, scrapped, approved amount

Amount ready for stock

Machine time, change over time

Cycle times and time per unit

Downtime, scrap with reason codes

To BI/ Excel

RS Production provides

Order times and amounts

Workshift times and amounts

Downtimes, scraps w loss reason codes

Cycle times and time per unit

From/to EAM (enterprise asset management)

RS Production provides

Machine cycle counter

Machine uptime

Machine downtime (breakdowns)

Work order requests

RS Production gets

Work order status (connected to each machine)

From/to machine equipment

RS Production gets

Current article/product

Current machine status

Uptime/downtime

Cycle counter

Scrap counter

Rework counter

Automatic reason code

Process values and measurements

RS Production provides

Current article/product

Current order/operation

Machine recipe/settings

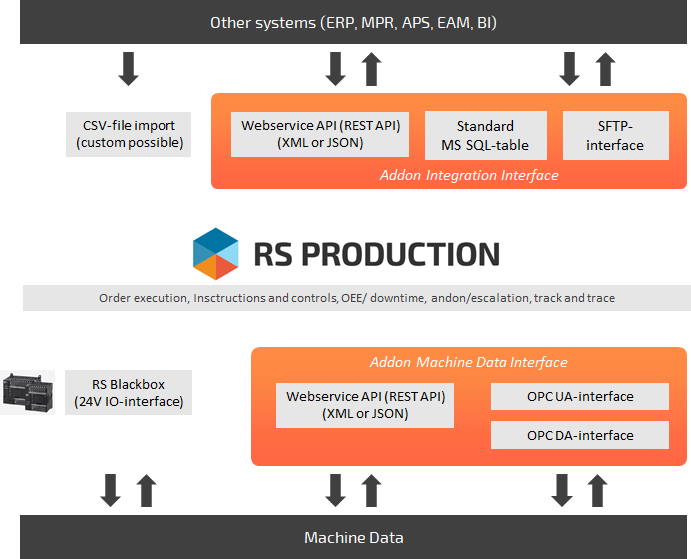

MES integration interfaces

RS Production have the following integration interfaces for MES. Read more details in Integration Interface and Machine Data Interface.