RS Production Screens

Screens is an addon for RS Production OEE and/or RS Production ACT.

A revolution for fact-based working methods

RS Production Screens gives you the right information at the right time in the right user interface. It drives faster reactions and reduced production losses.

RS Production Screens is a digital tool for creating participation and ownership by getting employees in different roles to work fact-based based on common current situation and problem images.

Without writing any code, you build your own real-time visualizations and report pages with a large selection of ready-made graphic components. This allows you to avoid expensive consulting costs and long lead times in future adjustments of visualizations.

With RS Production Screens, you can drive the right behaviors and decisions by showing the right information to the right person at the right time in the right user interface. It can be TV screens, e-mail, operator terminals or RS Productions' built-in report and analysis tools.

In an ever-changing world, reports and visualizations need to be constantly adjusted to remain relevant. In the easy-to-use interface in Office tools, you create, preview and publish the visualizations with a click-based configuration. This means that you provide the production organization with real-time updated decision material without writing a single line of program code.

And you adjust and adapt visualizations and reports on an ongoing basis without the need for help from product experts or external consultants.

Features

Put together and maintain your own visual report pages without coding.

Report pages can be shown on

TV-screens (user interface Info Screens)

In Operator tools

In Office tools' report and analysis tool

Drag and drop standard components to show

Current status

Production outcome

OEE and losses

Standard visual Screens components

The different RS Production products and addons add their own Screens components.

Go here to read a Overview of screens components

User guide

Go here for RS Production Screens user guide

Examples

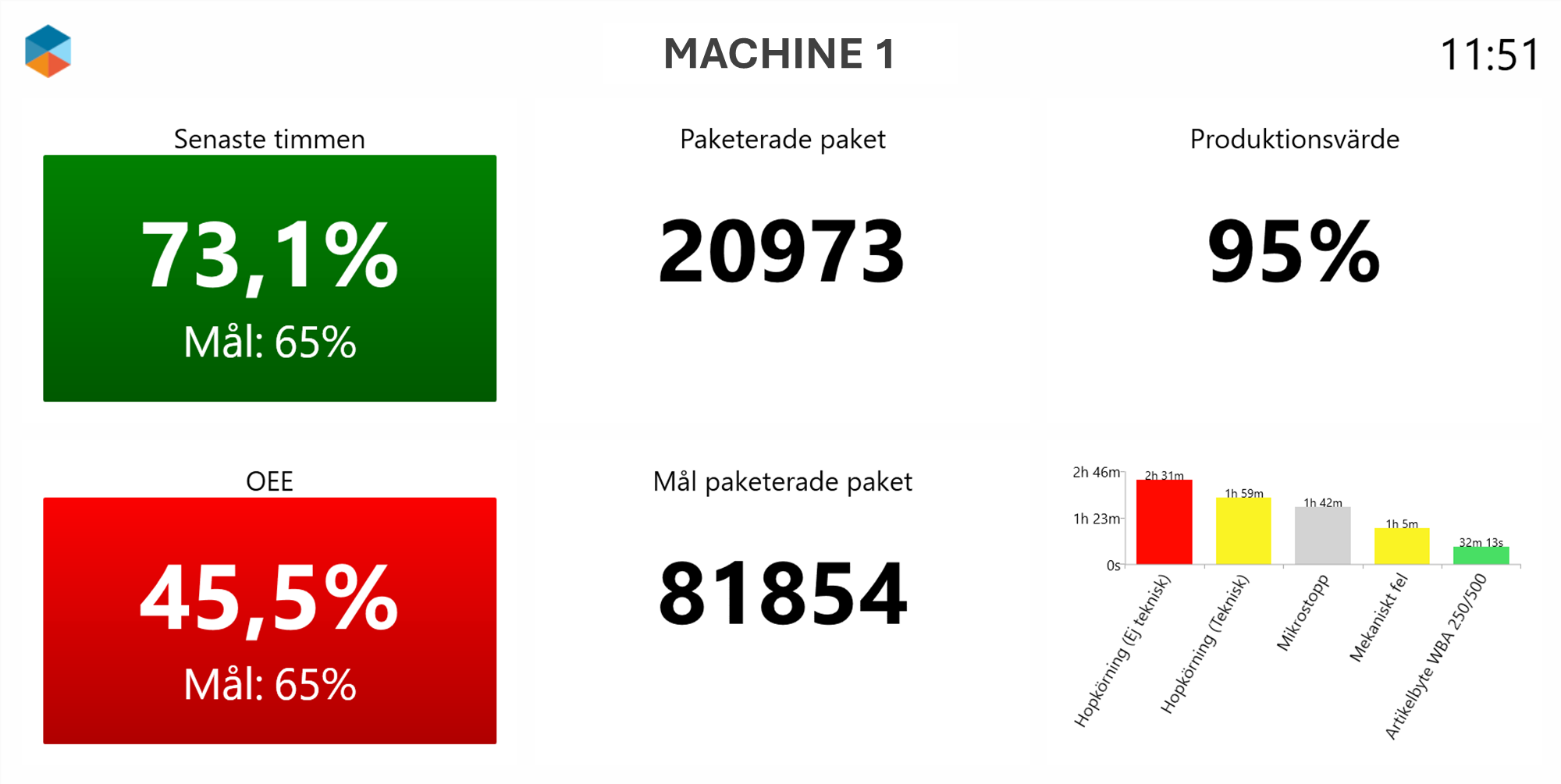

Single machine, cell or line

Last 60 minutes OEE, produced amount, uptime %

Ongoing 24h OEE, produced amount, top 5 loss reason

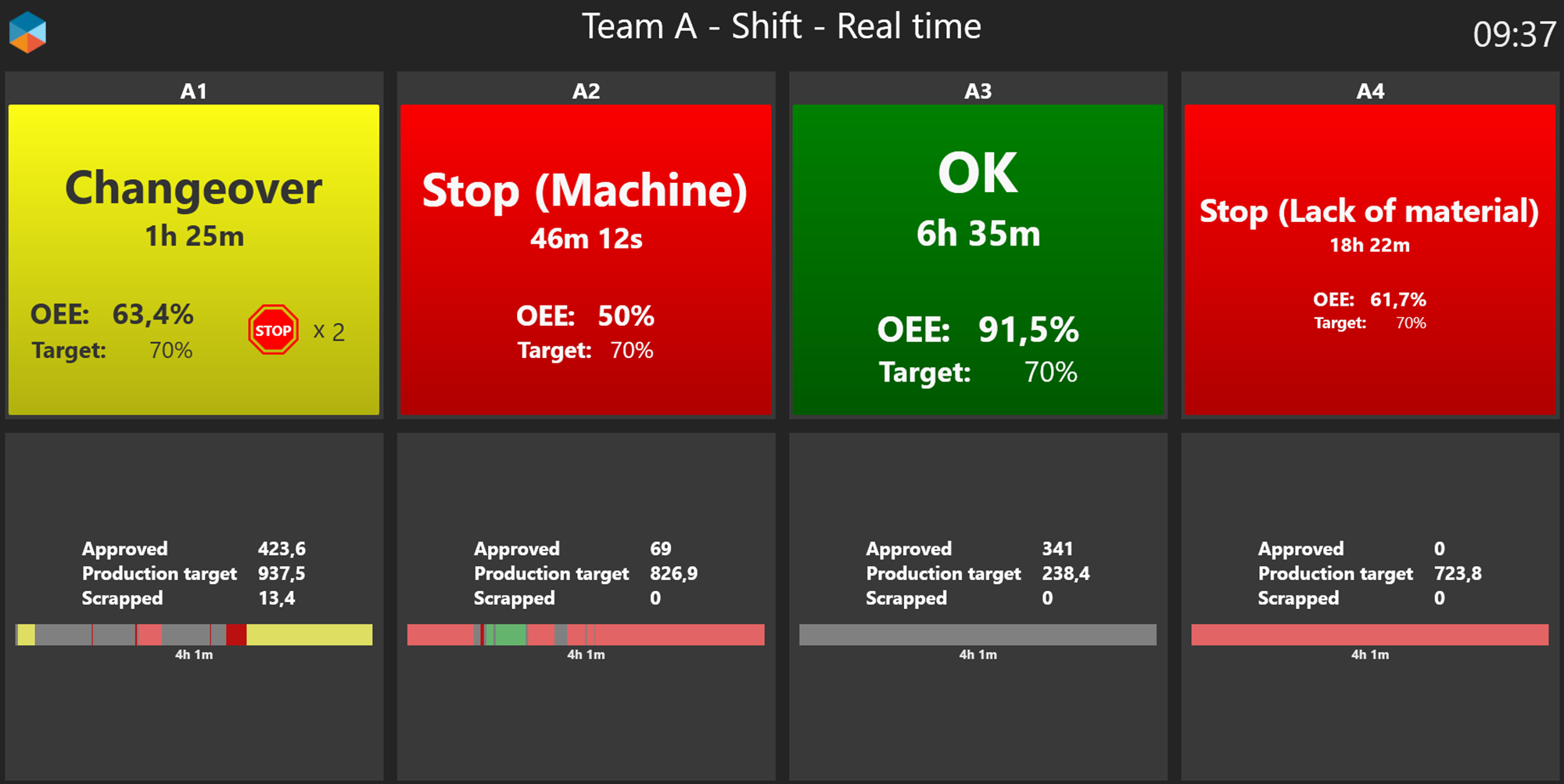

Machine group

Real time

Columns are Lines/cells/machines

Rows are

real time status (this shift) + no of stops without a reason code

produced + scrapped vs target + shift time line

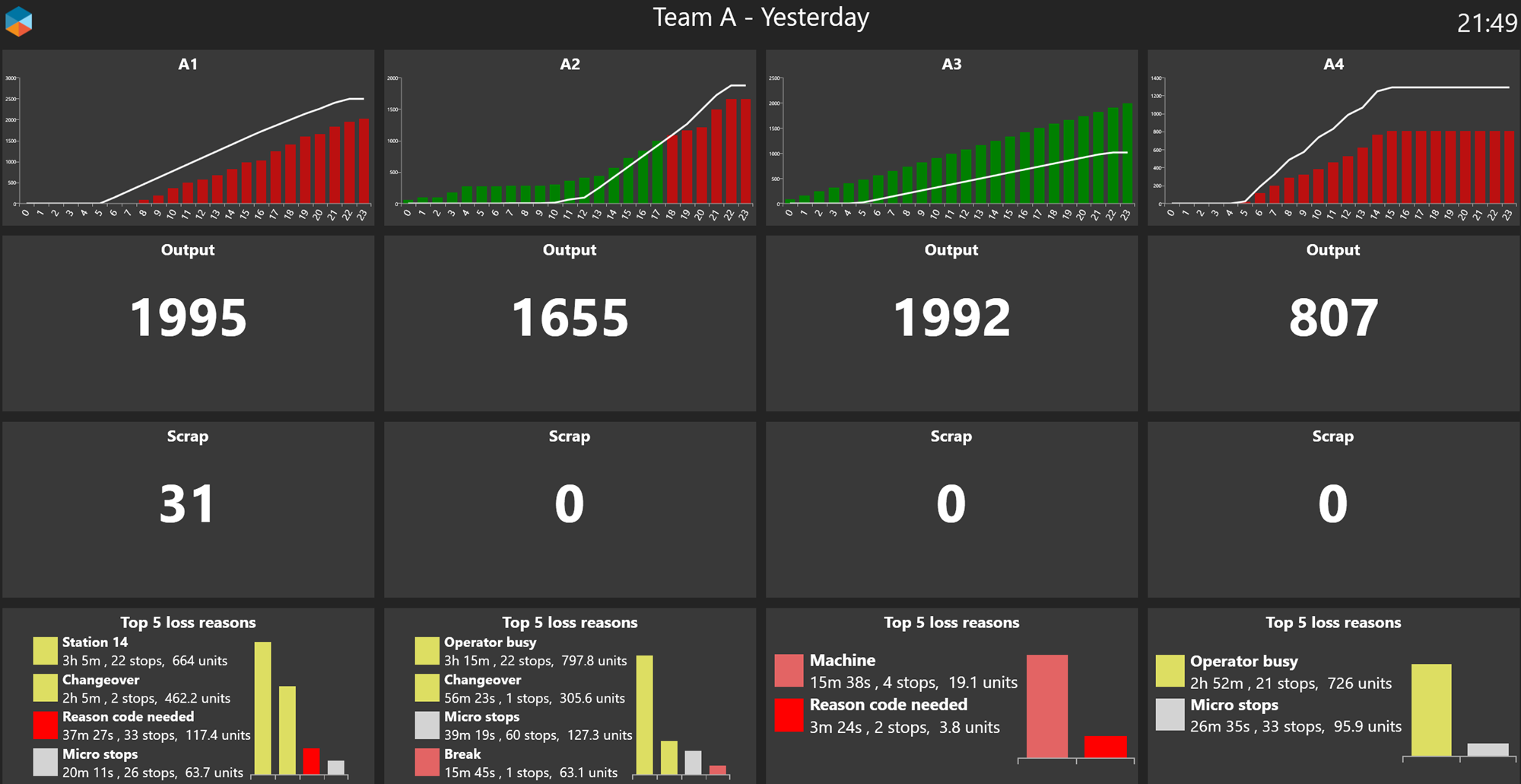

Daily summary

Columns are Lines/cells/machines

Rows are

approved amount vs target per hour

total approved amount

total scrapped amount

top 5 loss reason codes (time lost, no of stops, potential output lost)

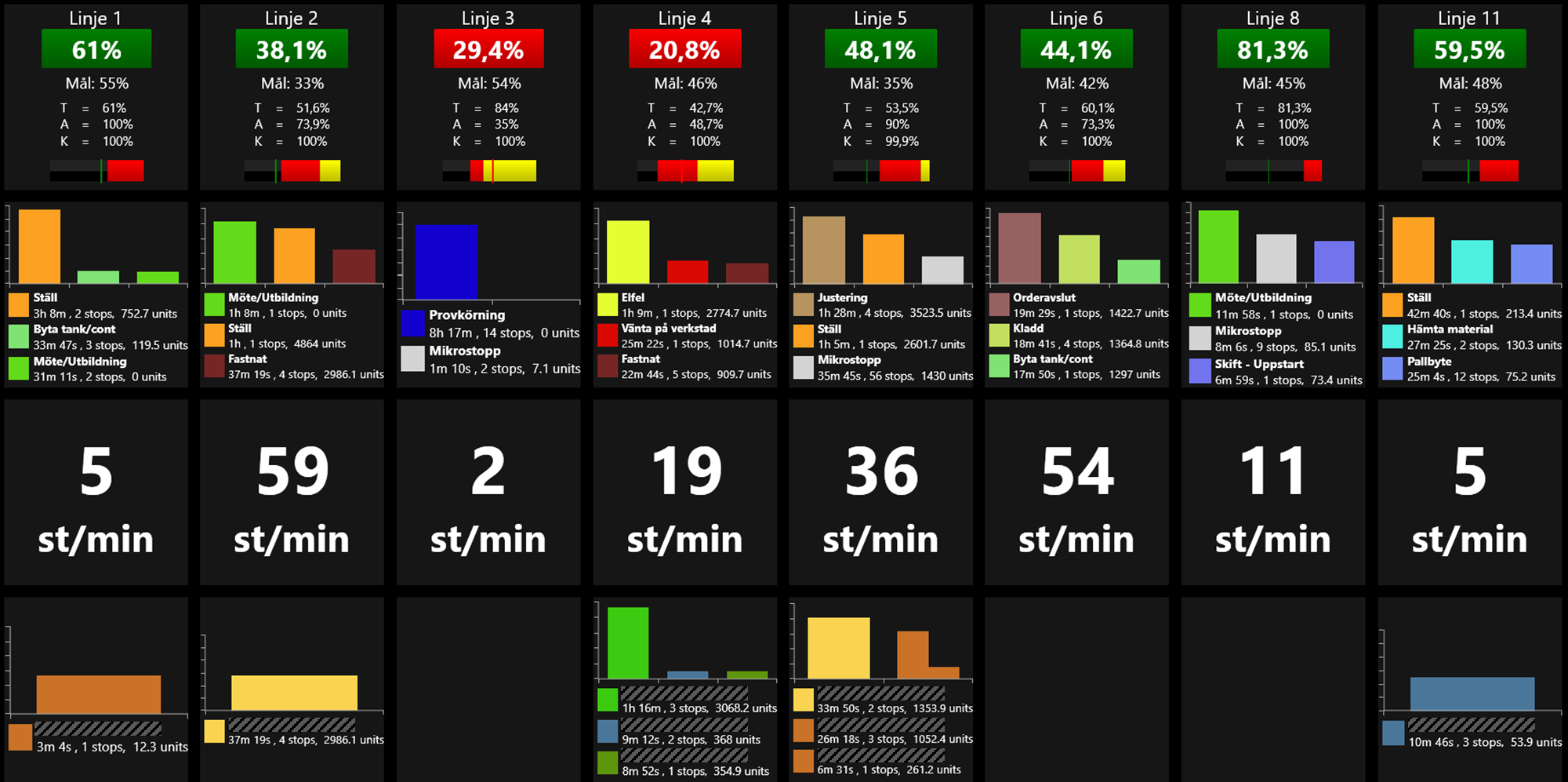

Full factory overview

Daily management

Columns are lines/cells/machines

Rows are

OEE vs target (incl breakdown into A/P/Q and OEE bar graph)

top 3 downtime reason codes (time lost, no of stops, potential output lost)

current machine speed

top 3 technical downtime reasons

Columns

Left column is full factory aggregated

Other columns are departments/teams/machine groups

Rows are

approved amount vs target per hour

total approved amount

total scrapped amount

top 5 loss reason categories (time lost, no of stops, potential output lost)

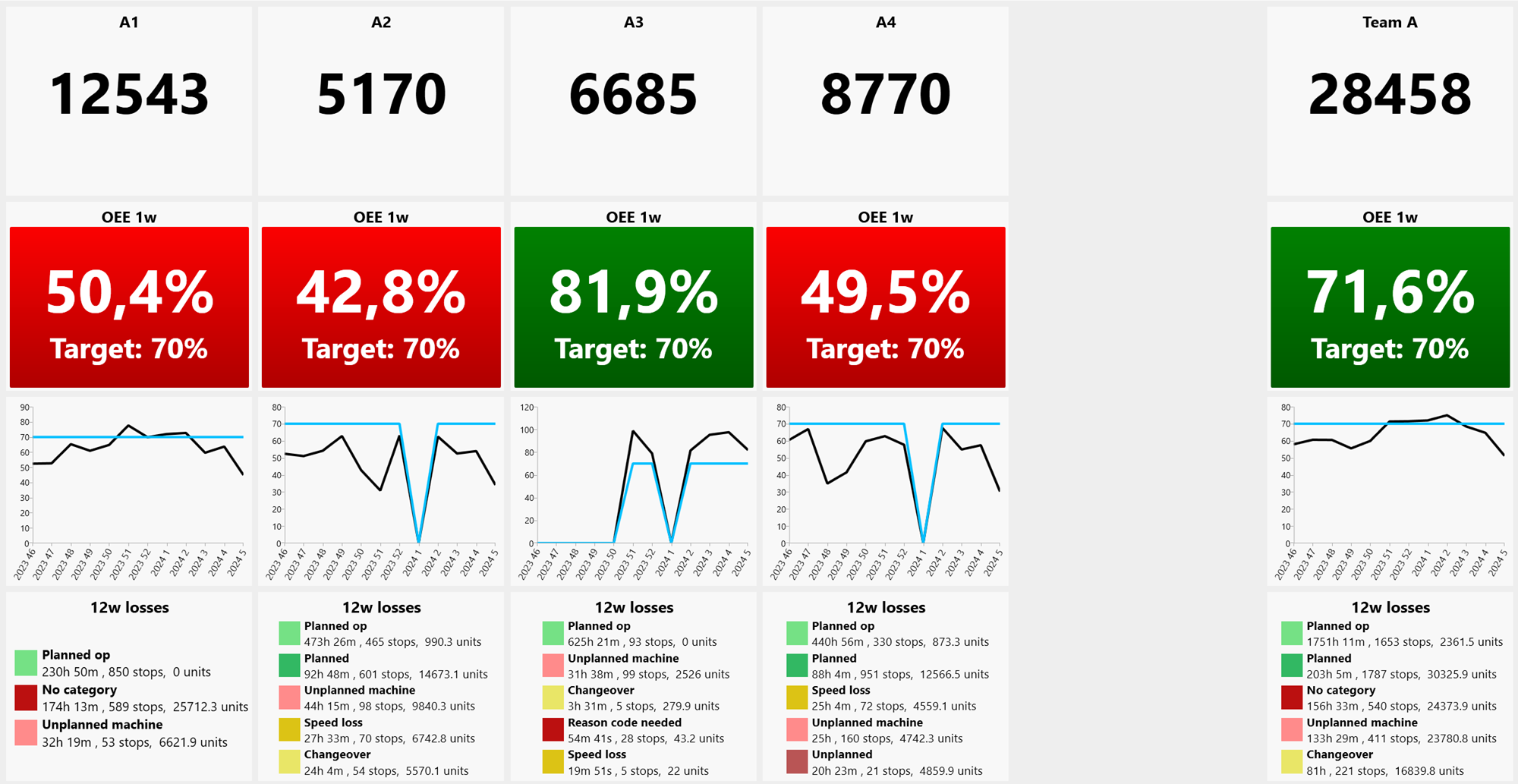

Weekly business review

Columns

departments/teams/machine groups

column to the right is full factory summary

Rows are

Output (amount that can be delivered to customer)

OEE vs target (explains cost level)

OEE per week last 12 weeks (explains cost development over time)

Loss reason categories (not reasons) last 12 weeks.

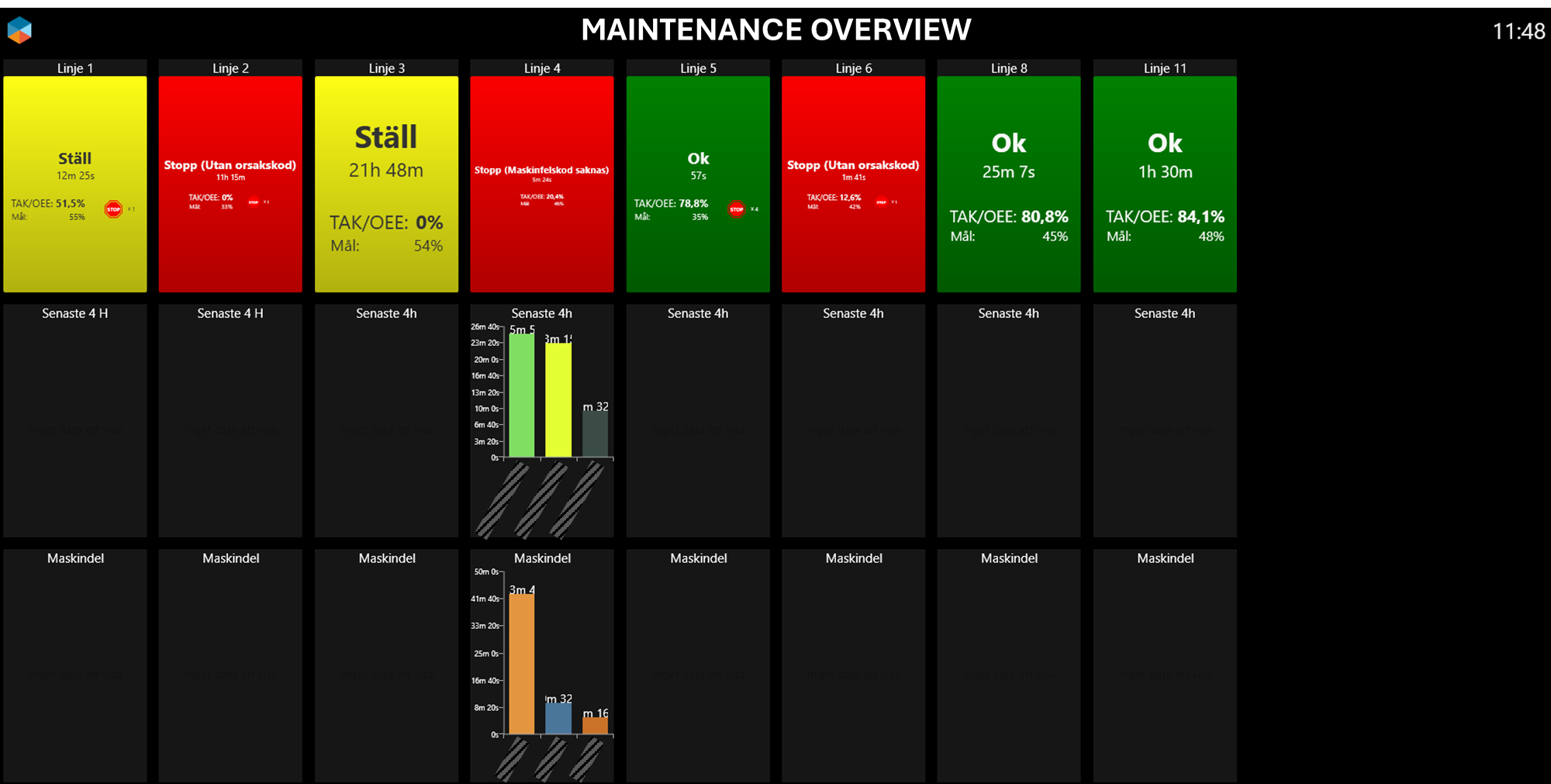

Maintenance

Full factory overview in real time

Columns are lines/cells/machines

Rows are

current machine status. Red if standing still.

technical loss reason codes last 4h

technical equipment/station loss codes last 4h.