Uptime, downtime and cycle times in RS Production

Everything with counting of produced amounts are included in

Everything with updown, downtime, speed loss and quality loss are included in

There are a few aspects to consider to get correct uptime and downtime.

Standard vocabulary

Uptime | Time when the machine is running |

Downtime | Time when the machine is unavailable for production. This includes all types of stoppages. |

Cycle Time | The time it takes to complete one operation or set of operations. |

Time per unit | time it takes to produce one unit, including Availability, Performance and Quality losses. This time is relevant when preparing the production plan |

RS Production specific vocabulary

Optimal Cycle Time | The shortest time the machine needs to complete the assigned operation with the right quality. This should not be confused with average cycle time or “the fastest cycle time we usually run with”. Setting the right Optimal Cycle Time is crucial to get the correct Performance loss and hence the true OEE value. One machine can have several Optimal Cycle Times as it can vary with products (articles). |

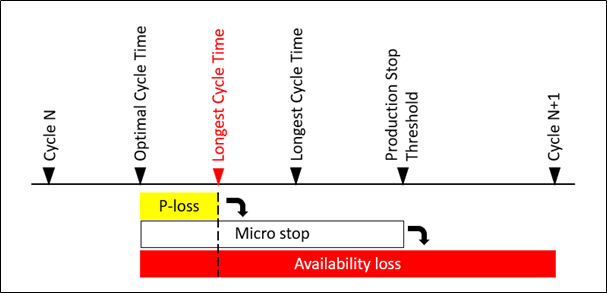

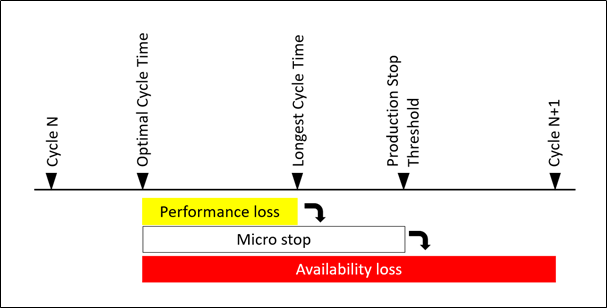

Cycle Time Limit (Previously Longest Cycle Time) | Determines when a speed loss (OEE Performance loss) turns into a stop (OEE Availability loss). We recommend that you set this parameter at a minimum to 10 seconds, and if you have longer cycles you should be generous. See explanation below. |

Micro stop limit (Production Stop Limit) | Determines when the stop goes from being a micro stop to a stop that should be given a stop reason. |

There are several ways of capturing machine data and measuring your losses with RS Production OEE. The following description is relevant when using cycle signals.

How Optimal Cycle Time, Cycle Time Limit and Micro Stop Limit plays in to Performance and Availability losses.

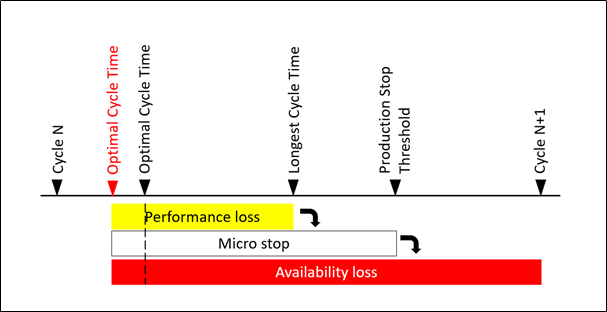

Consequences of setting to short Optimal Cycle Time

When setting the Optimal Cycle Time to short, it will result in faulty losses and an incorrect OEE value (to low).

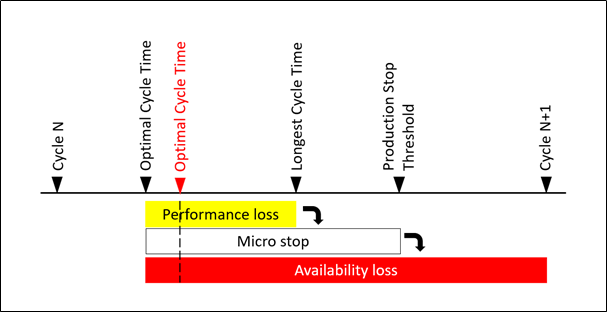

Consequences of setting to long Optimal Cycle Time

Setting the Optimal Cycle Time to long will result in hidden losses and indicate an incorrect higher OEE value.

Consequences of setting a too tight gap between Optimal Cycle Time and Cycle Time Limit

If you set this gap to tight, your Performance losses will be presented as Availability losses, and in the worst-case scenario, a stop will be reported for every product cycle. This can potentially burden the system and affect user experience.