Reason codes, categories and station codes

This is a feature in RS Production OEE

To provide the best possible data basis for analyses, RS Production has a few different terms for following up machine downtimes.

See Add and edit reason codes, categories, teams and folders for a step by step guide on how to manage reason codes.

RS Production offers different ways to catagorize downtime losses. A combination of reason code and station code gives you a good basis for identifying disturbance patterns.

Term | Meaning |

Stop reason | A stop reason explains WHY the stop happened (mechanical error, material defect etc.). Often it will be machine operators or technicians near the machine who selects the reason code. It can also be set automatically from any of RS Production’s different interfaces for machine signals. |

Stop category (optional to use) | The stop category is used to group reason codes on a higher level. Common categories are planned, unplanned machine related, other unplanned, changeover. The stop category is not visible to operators. It is pre-set hard-coded for each reason code. |

Station code (optional to use) | The station code relates to WHERE the stop occurred (filler, labelling machine). Describes what equipment (or part of equipment) that caused the stop. Often it will be machine operators or technicians near the machine who selects the reason code. It can also be set automatically from any of RS Production’s different interfaces for machine signals. |

Special station code “Machine” is used for maintenance indicators

![]() Note that the station code “Machine” have a special place in RS Production. It is used to calculate the maintenance related performance indicators in the maintenance reports. Read more about Report controls

Note that the station code “Machine” have a special place in RS Production. It is used to calculate the maintenance related performance indicators in the maintenance reports. Read more about Report controls

Technical availability

MTBF (Mean time between failure)

MDT (Mean downtime)

Station codes simplifies downtime follow up

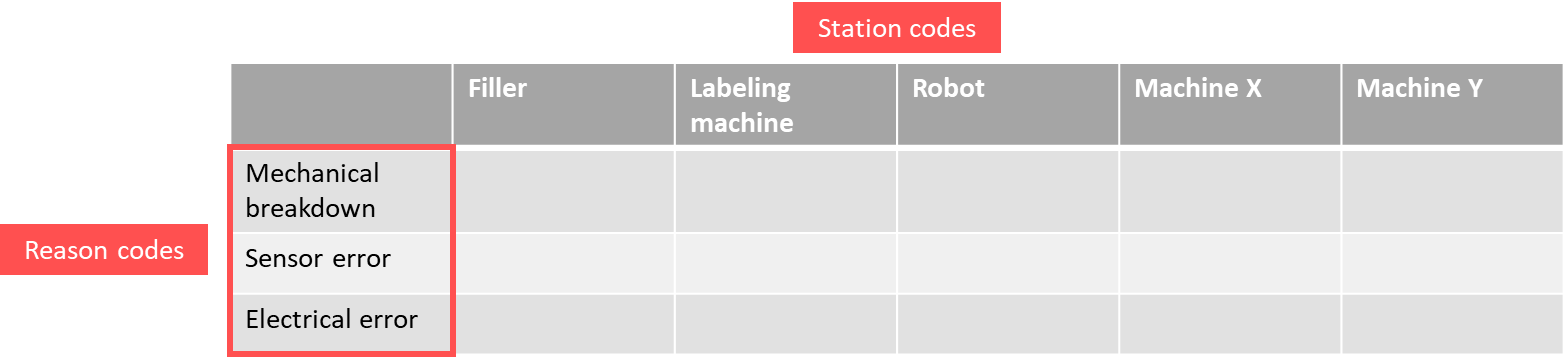

When not using stations, it quickly becomes a long list of reason codes. That makes it complex for operators.

Mechanical breakdown Filler, Mechanical breakdown Labeling machine, Mechanical breakdown Robot, Mechanical breakdown Machine X …

Sensor error Filler, Sensor error Labeling machine, Sensor error Robot …

Electrical error Filler, Electrical error Labeling machine, Electrical error Robot …

Reduce number of reason codes with stations

When working with stations, the number of reasons codes can be much less. That gives better user experience for operators. It is easier to find the right reason code when you have less to chose from.

In the example below, the bullet list from above is reduced to only 3 reason codes.

Visual examples

Illustration #1

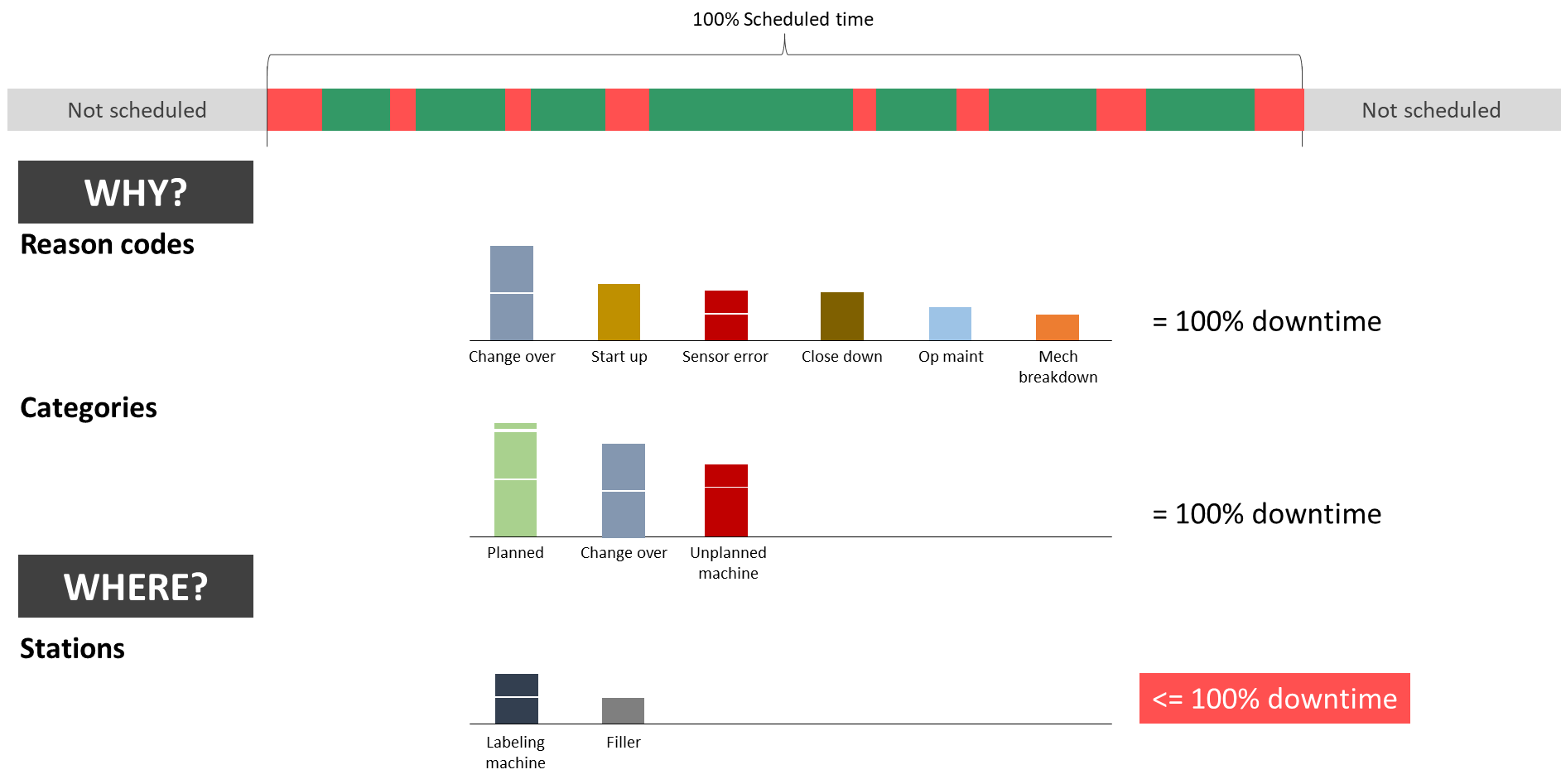

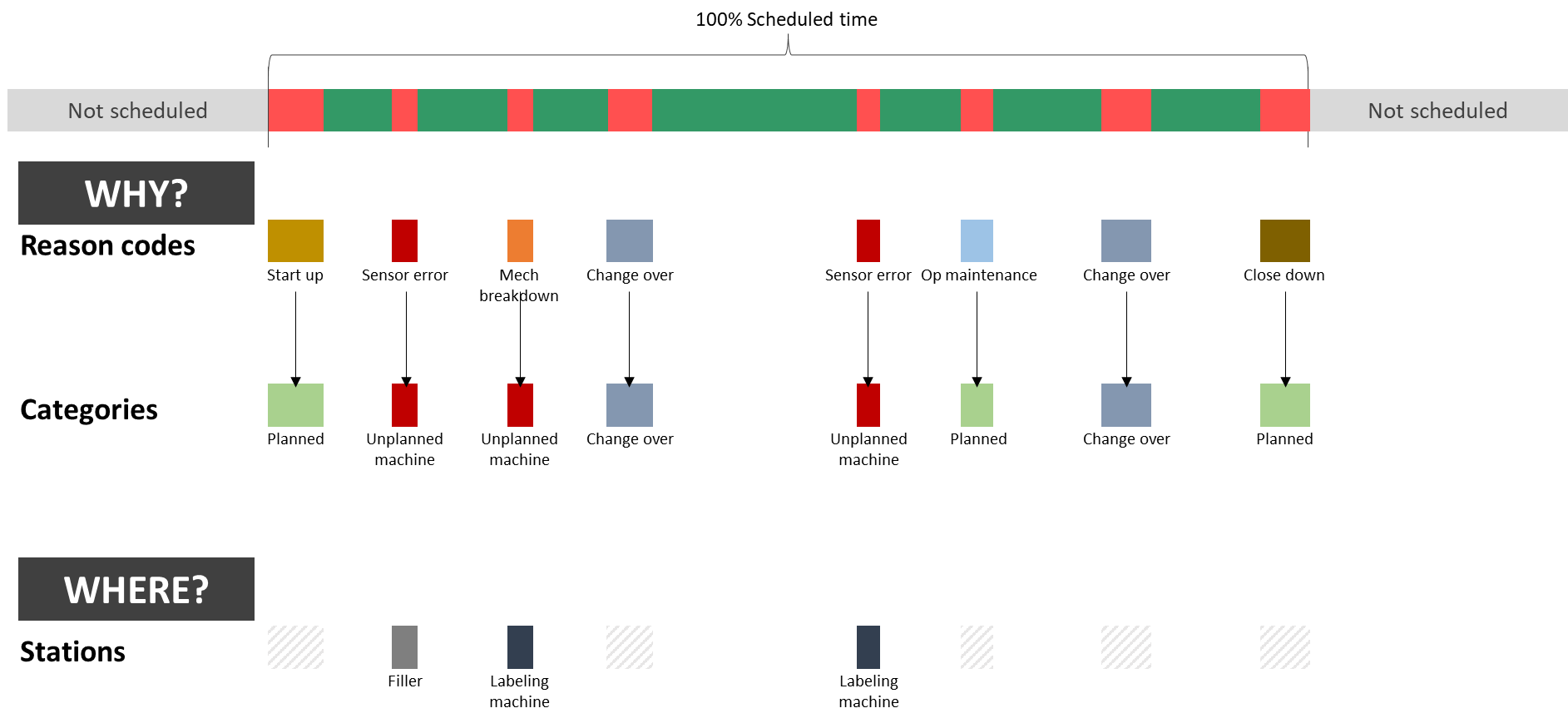

The time line below illustrates the relation between reason codes, categories and station codes.

Both reason codes “Sensor error” and “Mechanical breakdown” can be of the category “Unplanned machine related”

The two different stoppages with the reason code “Sensor error”, happened at different equipments. First one on the “Filler”, second one on the “Labelling machine”

Illustration #2

The illustration below shows the same time and example as illustration #1

Summarized, the reason codes explains the downtime. Reason codes cover 100% of the downtime.

Same downtime, summarized on ”category level” explains the situation on a higher level. Categories covers 100% of the downtime.

Same downtime, summarized on ”station level” explains what equipments that have caused downtime. Station codes does not necesary cover 100% of the downtime.