Performance loss

This is a feature in RS Production OEE

In OEE, performance loss represents the time when the machine is running, but is not running at the optimum speed.

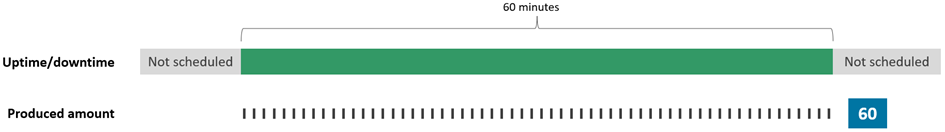

Simple calculation example

Optimum speed = 60 units per hour. This is the expected produced amount when everything runs perfect.

Produced amount = 60 units

Performance = produced amount / optimum amount

Performance = 60 / 60 = 100%

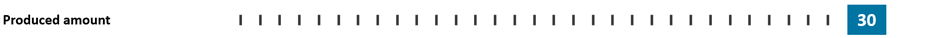

Produced amount = 30 units

Performance = produced amount / optimum amount

Performance = 30 / 60 = 50%

🤓 Note that Optimum speed sometimes is called “design speed” or “name plate speed”.

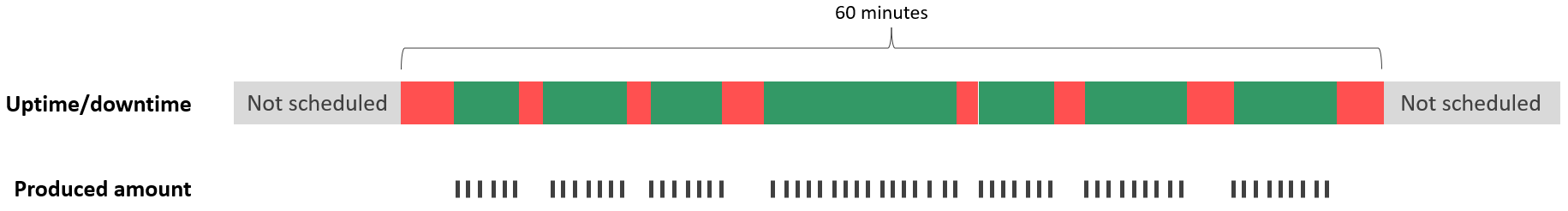

Based on running time only

Downtime (red time) is not included in the performance calculation. Only the uptime/running time is included.

Clock time = 60 minutes

Uptime = 40 minutes

Optimal cycle time = 60 s → Optimum amount = 60 units /h

Optimum amount = 40 units

🤓 Note that “Plannable speed” and “Effective time per unit” includes efficiency losses, and is different from optimum cycle time

Produced amount in different production processes

Of course, produced amount is differently expressed in different factories

Units per hour | Units per minute | Cycle time |

|---|---|---|

Products/hour, Kg/h, Meters/h | Products/min, Kg/min, Meters/min | Seconds/product, Seconds/meter, Seconds/… |

3600, 1000, 20 | 60, 16.67, 0.33 | 1 s, 3.6s, 180s (3 min) |

Products has different Optimum speed

Different products (articles) can have different optimal cycle time

Article/product | Optimal cycle time | |

|---|---|---|

Potato chips - 100g bags, Line A | 1,8 seconds | 2 000 bags per hour |

Potato chips - 250g bags, Line A | 3,0 seconds | 1 200 bags per hour |

Also, the same product can have different optimum cycle time in different machines (measure points)

Article/product | Optimal cycle time | |

|---|---|---|

Potato chips - 100g bags, Line A | 1,8 seconds | 2 000 bags per hour |

Potato chips - 100g bags, Line B (new) | 1,2 seconds | 3 000 bags per hour |

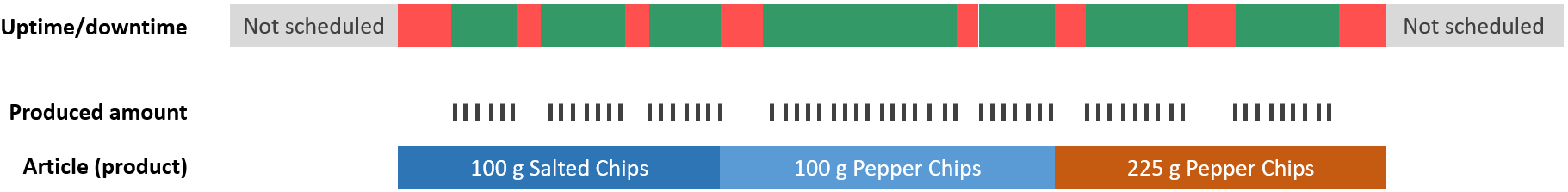

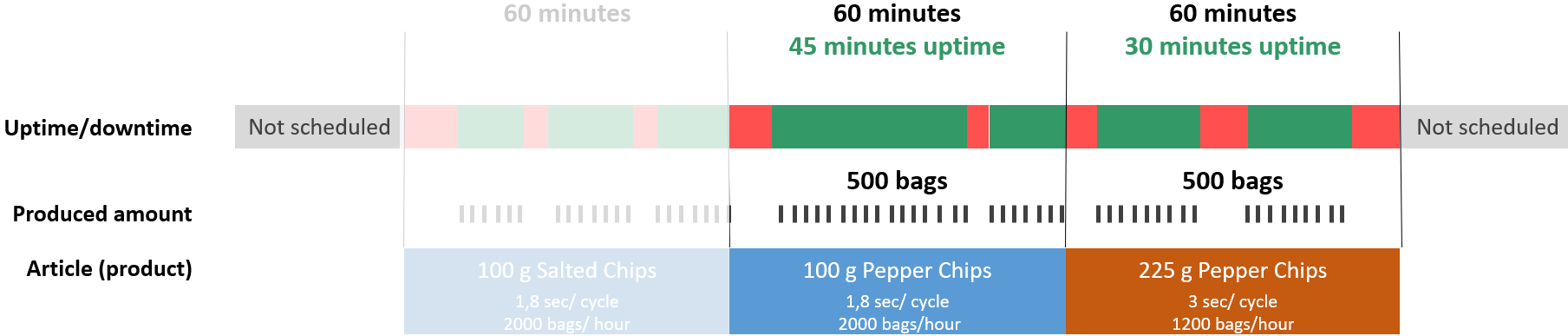

Example

As mentioned above, downtime (red time) is not included in the performance calculation.

Clock time = 1h + 1h = 2h

Uptime = 0,75h + 0,5h = 1,25h

100g Pepper chips | 225g Pepper chips | |

|---|---|---|

Optimal cycle time | 1,8 sec per bag | 3 sec per bag |

Optimum amount | 2 000 bags per hour | 1 200 bags per hour |

Optimum amount = (0,75h x 2000) + (0,5h x 1200) = 1500 + 600 = 2 100 bags

Produced amount = 500 + 500 = 1 000 bags

Performance = produced amount / optimum amount

Performance = 1 000 / 2 100 = 47,6%