RS Production Energy

Reduce energy cost and CO2e per unit

Energy consumption in production is costly and the main part of your factory’s Scope 1 emissions. At the same time, it can be abstract and hard to visualize.

RS Production Energy help you understand your production energy usage and see where you wasting energy, CO2e and cost without creating any customer value.

RS Production Energy can be run as stand alone or together with RS Production OEE.

Read this paper on how to reduce 20% energy consumption

Support for the ESRS report

ESRS reporting begins in 2025, requiring companies with revenue over €50 million to disclose sustainability-related information.

ESRS stands for European Sustainability Reporting Standards. These standards are part of the Corporate Sustainability Reporting Directive (CSRD) implemented by the European Union.

Go here to read more about the sustainable factory and ESRS reporting Sustainable factory.

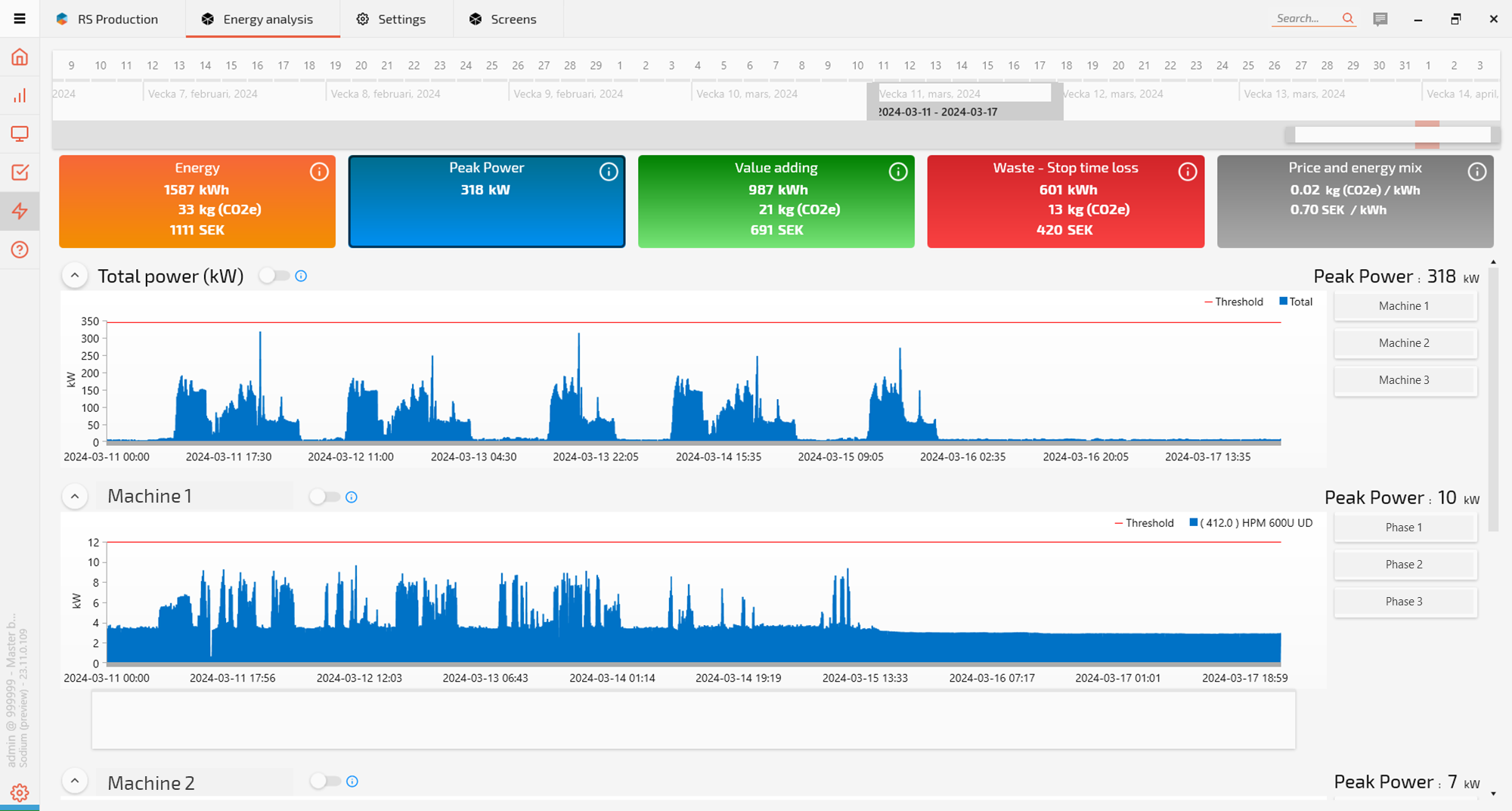

Energy usage down to machine and equipment level

RS Production is easy to connect. It includes all hardware you need and is connected directly to our cloud service without connecting to your local network.

Energy usage down to article and product level

When running together with RS Production OEE, you’ll get facts down to article level.

Direct CO2 footprint per article and unit

Direct energy consumption per article and unit

Direct energy cost per article and unit

Facts for improvements

The purpose of RS Production Energy for improvement work is to measure energy consumption, energy cost and CO2e over time and put it in context with other production and disturbance follow-up. It then provides facts for improvement work to prioritize and follow up the effect of measures.

Measure any type of energy consumption

⚡Electricity consumption

1-phase and 3-phase are collected in real time with the included ammeter clamp or with a MID meter with pulse output. The pulse output describes how many watts have been consumed.

💧Gas, water and other media

Collected in real time with a sensor with pulse output. The pulse output describes the amount of media consumed.

Easy to connect

Current clamps are mounted without any need to stop the machines and will not cause any interruption in the manufacturing process.

RS IoT connects to the cloud directly through the mobile data network and is totally stand alone from your local network. Therefor, it will not be effected by any cyber security policys.

Features

CO2e

RS Production Energy calculates the Scope 1 CO2e emissions based on the energy used and either the current energy mix or your settings for CO2e per energy unit.

CO2e is presented per

Machine

Produced unit

Energy cost

RS Production Energy calculates your direct energy costs based on the energy used and either the energy cost in public databases or your setting for cost per energy unit.

Energy cost is presented per

Machine

Produced unit

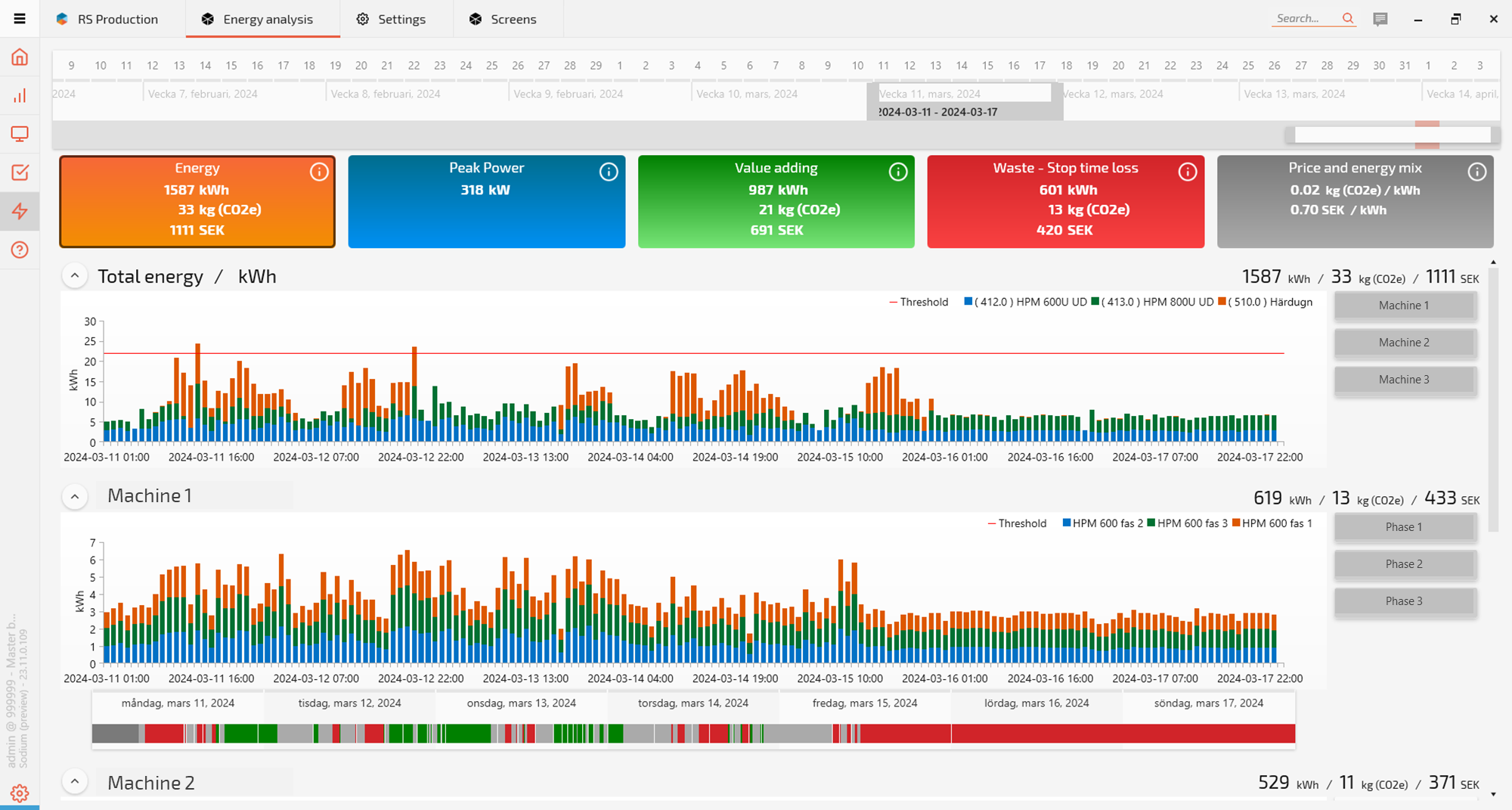

Energy consumption (kWh)

How many kWh different machines and production processes consumes.

Peak power (W)

How many Watts are different equipments consuming at different times. Are there peaks? Are the simultanous peaks on several machines?

Office tools reports

Energy

Energy consumption aggregated for the factory.

Also, per machine on a timeline together with the OEE-timeline for the machine (value adding/ non value adding time) visualizes energy consumption without any customer value added.

Power

Power usage per machine and for the factory. Peak power is shown clearly.

Red line shows a threshold that is adjustable.

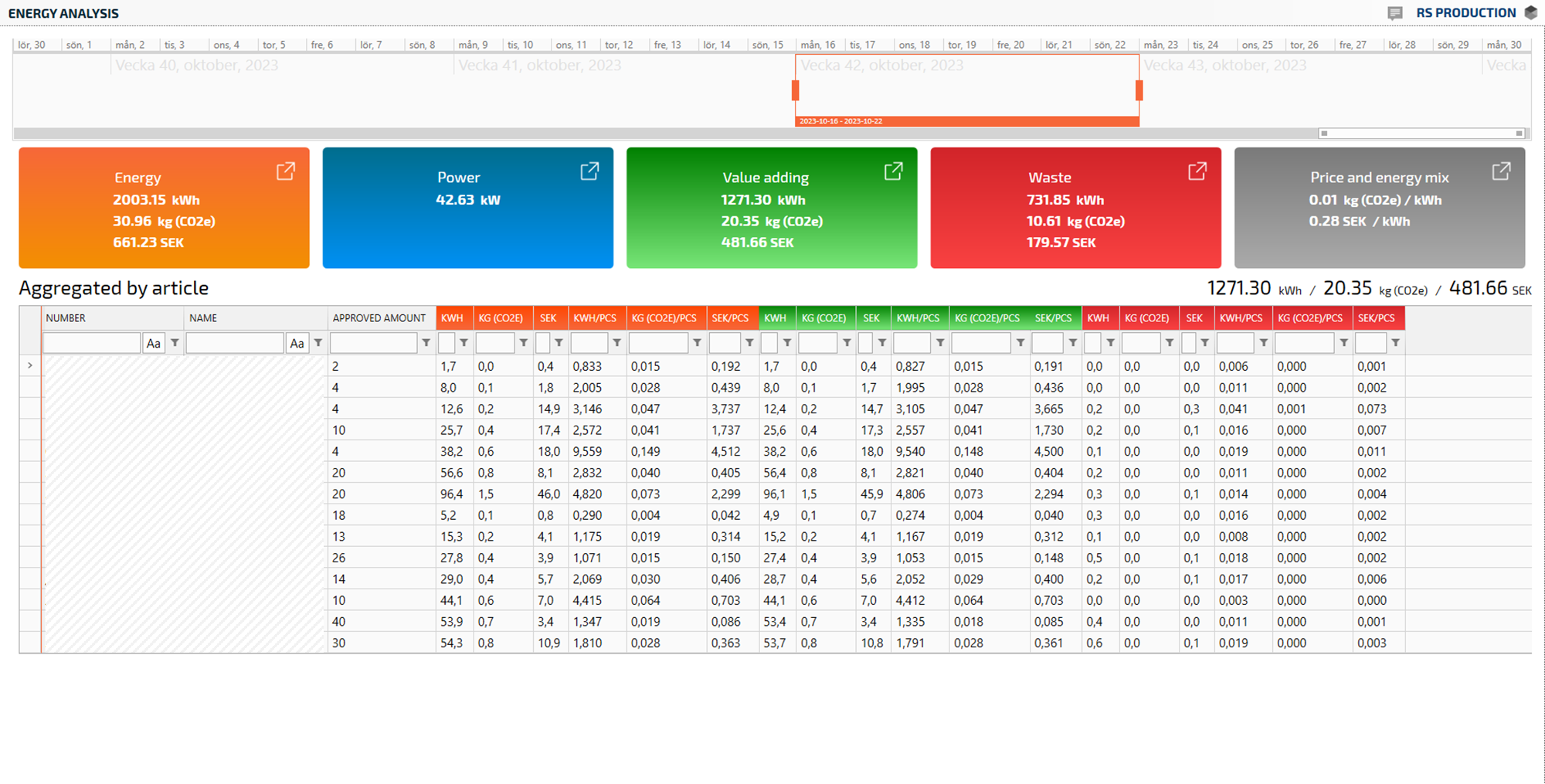

CO2, kWh and energy cost per product and unit

Energy consumption, CO2e emission and energy cost per article (type of product).

Also, split between value adding and non value adding time.

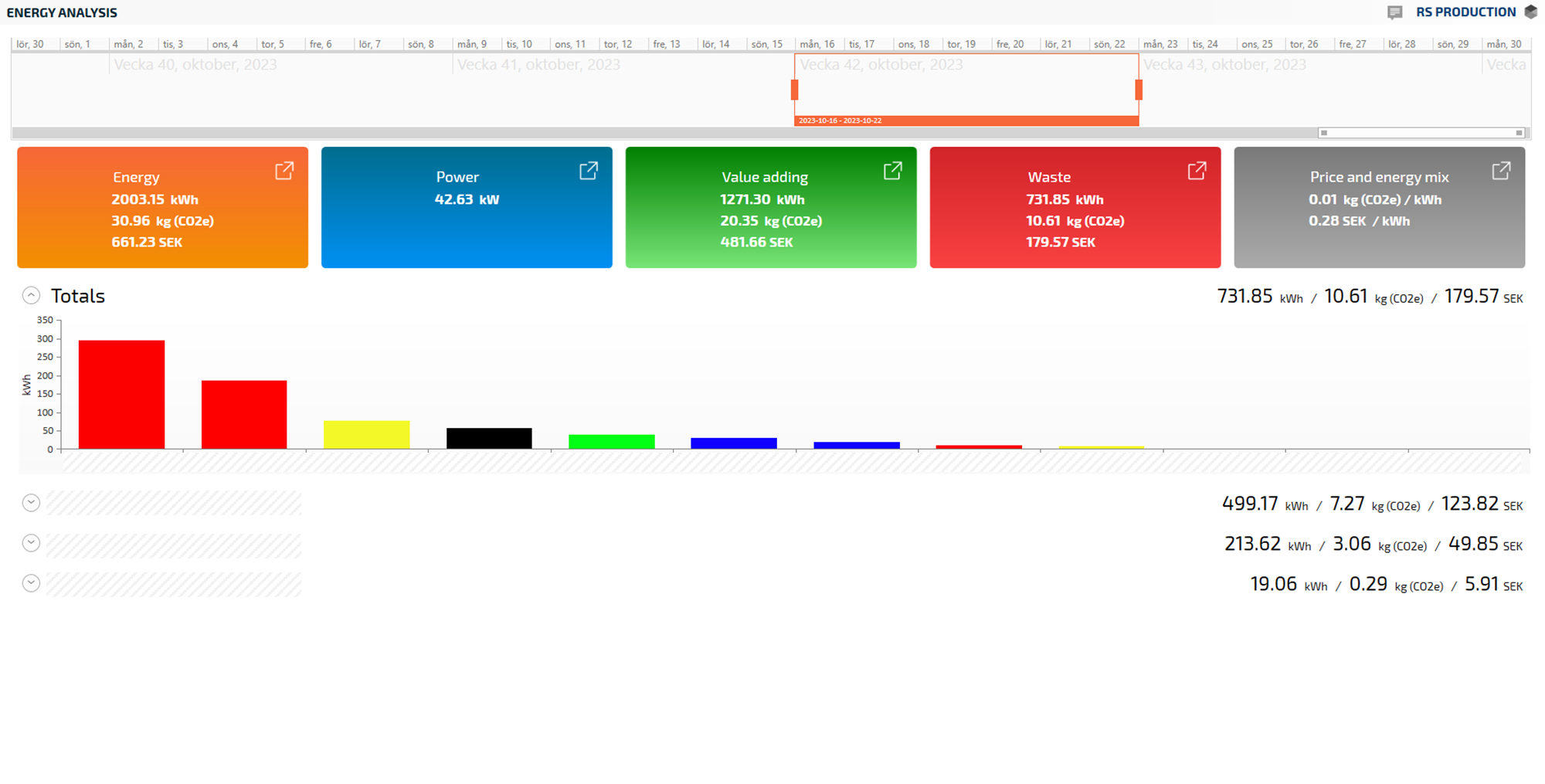

Reasons for energy losses

Energy loss pareto chart.

Understand what losses to reduce to get the most reduced energy consumption per unit.

Hardware Devices

Current clamps / Ampere meters

Ampere meters in different sizes can be connected to RS IoT with 3,5mm tele connector. It can be 1-phase or 3-phase.

Go here to read more about the RS IoT - Current Clamps

Pulse based meters

Pulse based meters for electricity or gas can be connected to RS IoT but are not included in the price. It can be 1-phase or 3-phase.

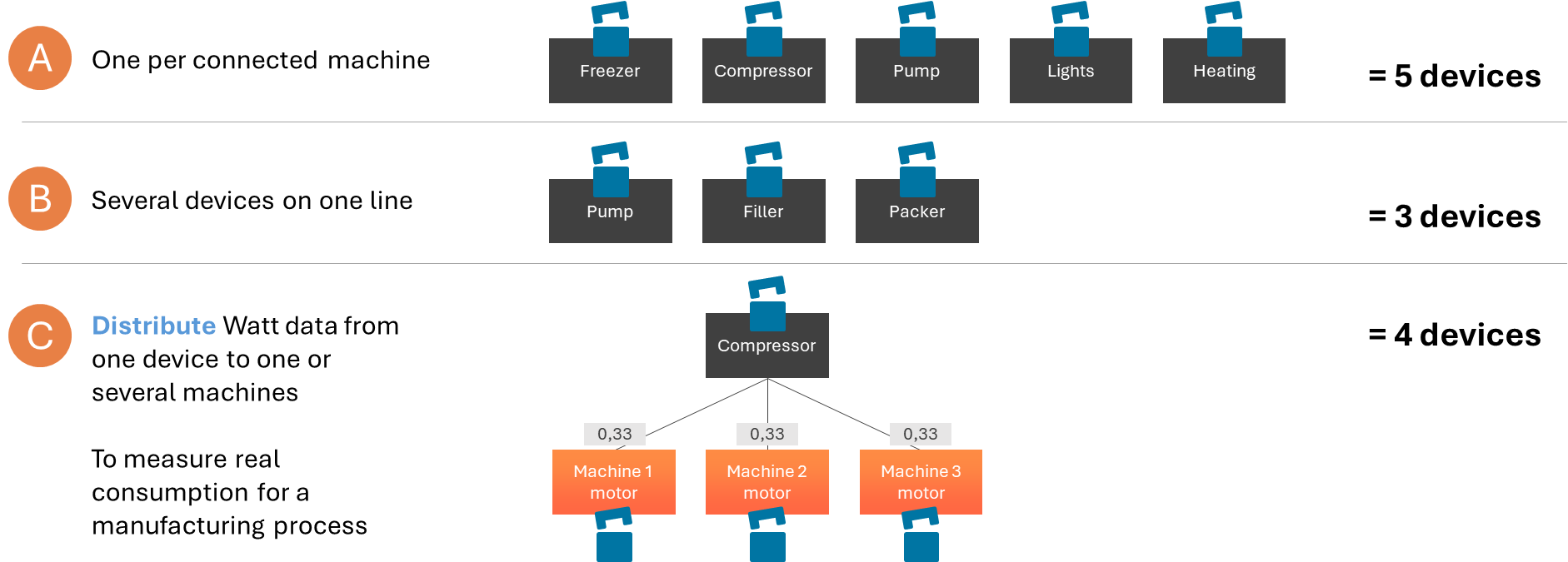

Combine consumption from several equipments

The energy consumed by one device (motor, fan, pump, compressor …) can be assigned to one or more machines in RS Production OEE.