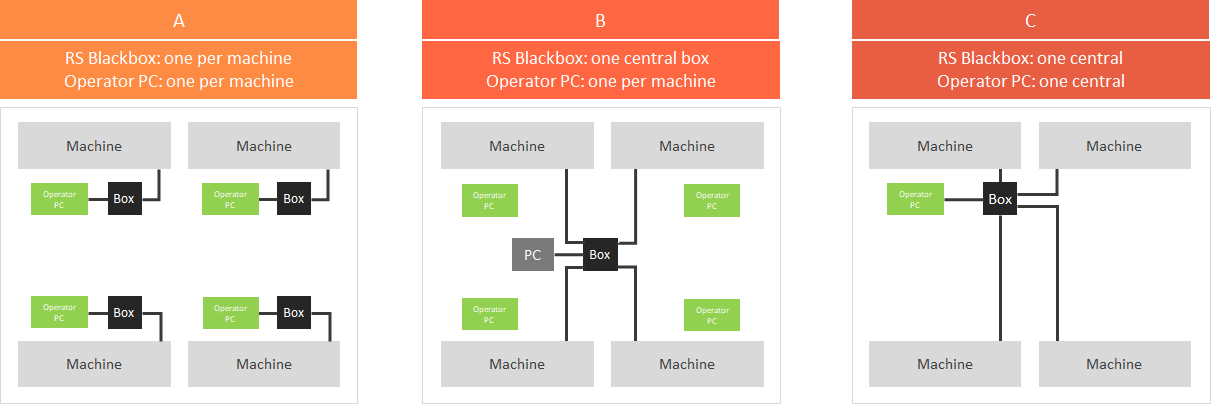

Different measure point setups, and how much hardware will you'll need?

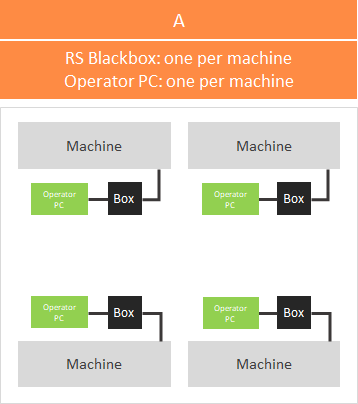

A - One piece of hardware per machine

4 x Measure point

4 x RS IoT

4 x PC for logging and Operator tools

Advantages

User interface very close to where operators runs the machine/station

Operator tools has instant access to machine data even without connection

to the central server and real time data is therefor not at all depending on

infrastructure like database/server/networkEasy to document, support and maintain hardware connection and setup

No risk that power shut down on one machine effects the data collection

at another machine

Risks

No known risks

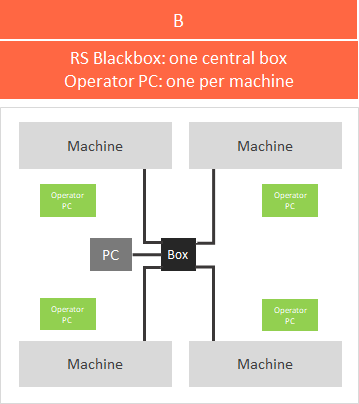

B - One central RS IoT and local Operator tools PC for each measure point

4 x Measure point

1 x RS Blackbox

4 x PC for Operator tools

1 x PC for logging machine signals

Advantages

User interface very close to where operators runs the machine/station

Easy to overview all machine signals on one central spot

Possible to maintain the logging PC without disturbing the Operator

tools PCsReduces hardware costs

Risks

Problems with network/sever/database will effect the real time

updates on the Operator tools clients.

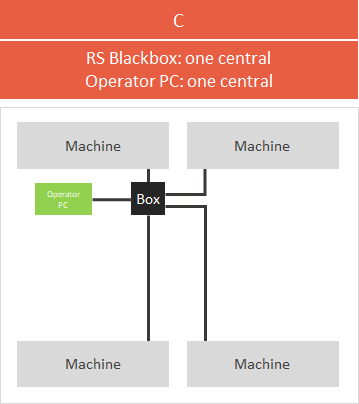

C - One central RS IoT and one central Operator tools PC for several measure points

4 x Measure point

1 x RS IoT

1 x PC for logging and Operator tools

Advantages

Easy to overview all machine signals on one central spot

Maximum reduction of hardware costs

Risks

Operators don’t have Operator tools available on all machines and must

remember to go to the central Operator tools clientProblems with network/sever/database will effect the real time updates

on the Operator tools clients.