More profitable and sustainable manufacturing.

All types of manufacturing processes consume energy. This means an energy cost. At the same

time, all energy consumed comes with an addi-tional CO2 e emission.

However, a large part of the energy consumption in manufacturing companies is pure waste.

Resource consumption without creating customervalue. It can be machines in idle mode and equip-

ment that consume more energy than necessary (when they perform something adding value and

when in idle mode).

For the manufacturing company, it means costs without revenue.

At the same time, this means utterly unneces-sary CO2e emissions.This means that much of an

end product’s CO2 e footprint consists of energy consumed without adding value or doing anything

else necessary to take the product to the end user.

Close to 50% of machine time is not value-creating.

Based on over fifteen years of experience helping manufacturing companies identify time and

resource losses, we can say with confidence that, on average, only about 55% (OEE) of a machine’s

planned production time is used for something creating value. Most of the time, the machine is idle

and consumes energy.

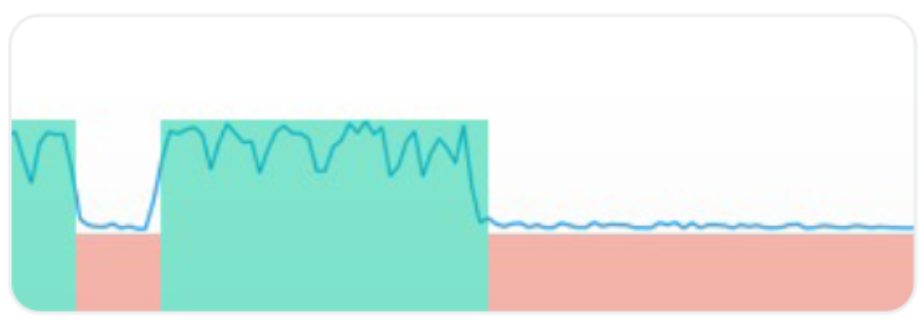

The graph shows how a machine changes between operation (green) and standstill/idling (red) over

time. The Y-axis shows how energy consumption varies. In this example, the idle machine continues

to consume about 40% of the energy that the manufacturing machine consumes.

Idle machines continues to consume energy.

Like a car at a red light, an idling machine consumes energy. When we measure energy consumption

in idle mode with our customers, we see that machines in hourly mode use 20–80% of the energy

that a manufacturing machine does without adding any customer value.

A large part of the energy consumption is lost.

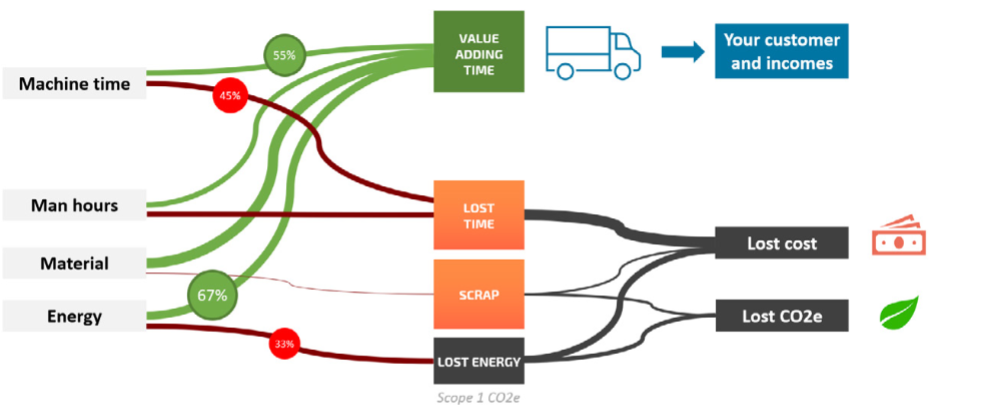

The illustration above summarises that direct resources in manufacturing processes are only

partially used for value creation, and the rest create both lost cost and CO2 e.

From our own experience, we know that the automated manufacturing industry, on average,

uses around 55% (OEE) of machine time for value-creating activities. The remaining (on average)

45% is lost machine time.

We also know from experience that (on average) a few per cent of the material is discarded; the rest

is used for something creating value.

Our empiric measurements on customers’ equip-ment confirm the same findings as Chalmers

Institute of Technology. Around 67% of the energy consumed in manufacturing is used for value

creation. About 33% is lost energy consumption.

The conclusion is that inefficient use of resources in general and energy, in particular, are lost costs and

unnecessarily consumed CO2 e.